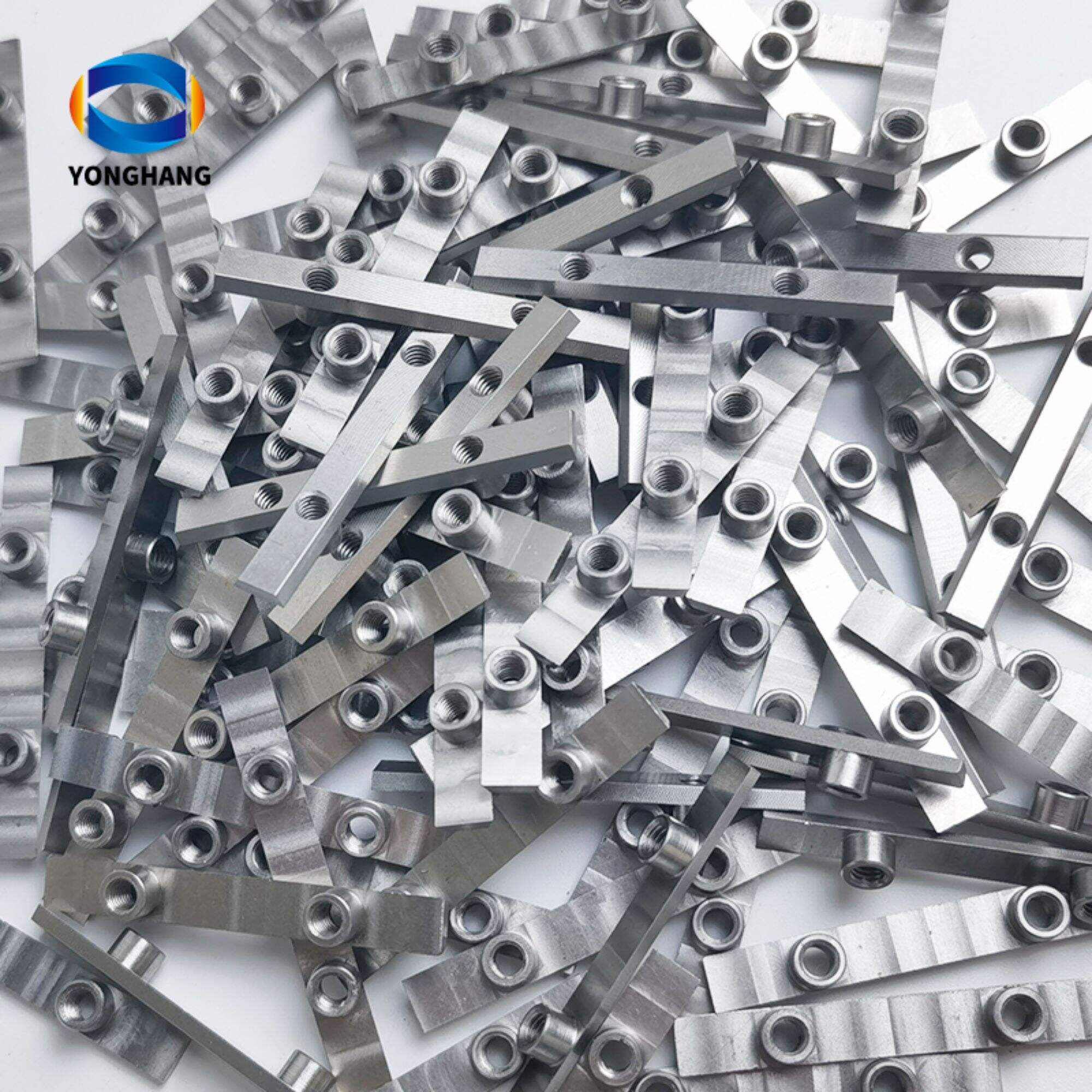

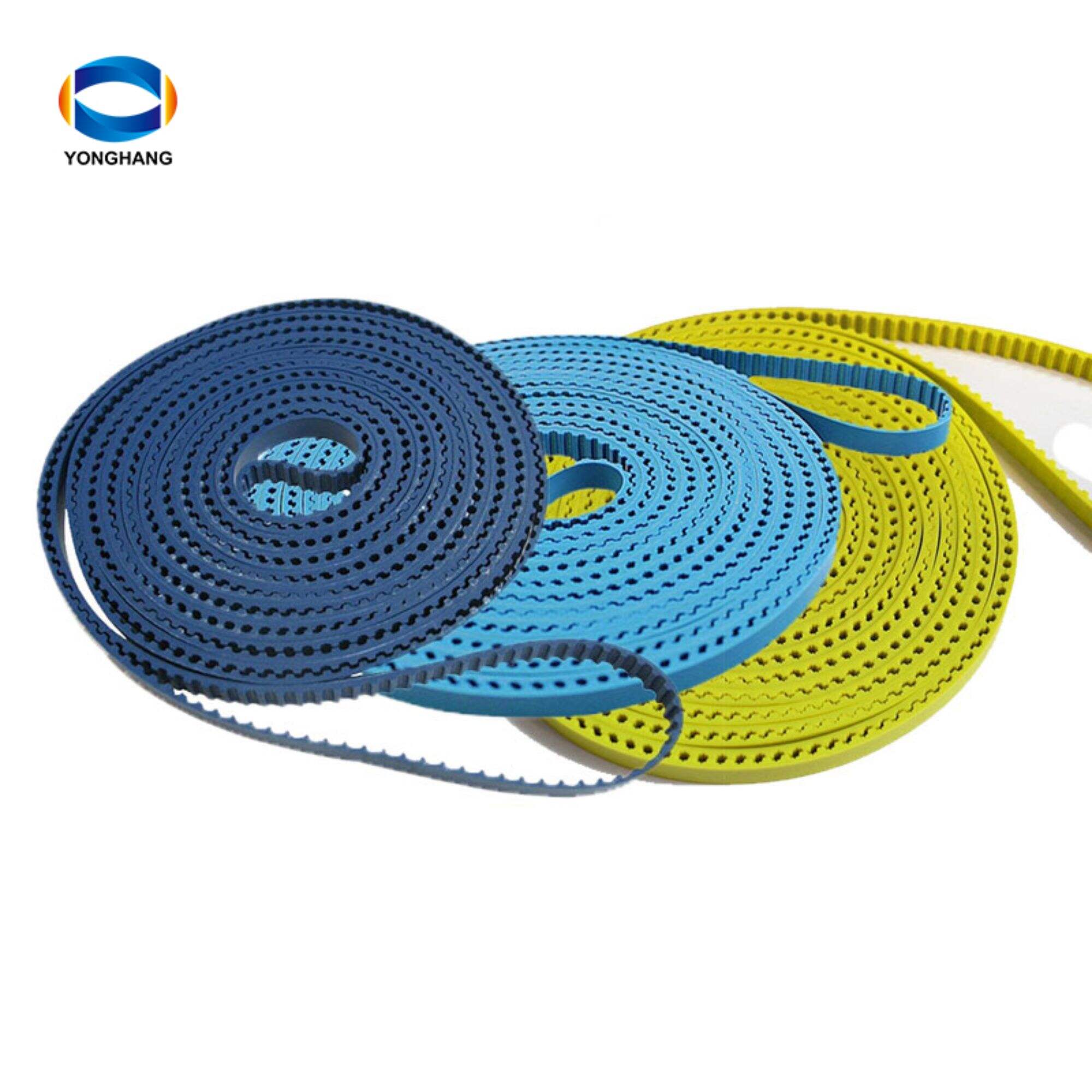

Guangzhou Yonghang Transmission Belt Co., Ltd. was founded in 2014, is a focus on rubber belt research and development manufacturer. Yonghang company has 10000 square meters of production base, the introduction of domestic and foreign advanced manufacturing equipment more than 50 units, and so on. Mold more than 8000 sets, an annual output of various types of rubber belt 500,000. The main products for the rubber belt series of products, such as coated timing belt, rubber flat belt, rubber haul off belt, PU timing belt, ATM belt, sausage belt, printer Belt, Conveyor Belt,Pulley,and so on.

YONGHANG company strictly implements IS09001 international quality certification, from design, raw materials, to production, every detail is excellence, only for high quality! Our products are widely used in printing carton packaging equipment, pipe wire and cable traction equipment, food packaging film equipment, wood chopsticks carpentry equipment, and so on.

YONGHANG offers a wide variety of standard items and special products designed to satisfy specific customer requirements.

We have professional Engineers and a skilled Quality Assurance team to make sure that we can constantly offer our customers high-quality products. Our experienced sales team will help the customers to find out whatever they are seeking and then to settle any after-sale issues.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY