Zip-link Belt for Corrugated Carton Industry

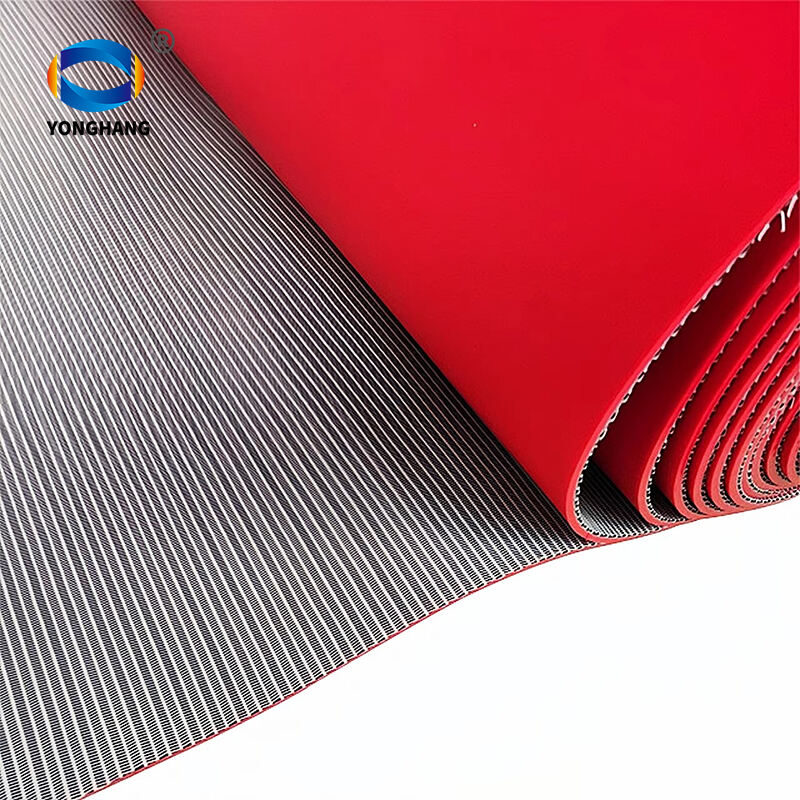

ZipLink belt uses a unique combination of traditional rubber cover materials and a structured spiral link mesh to make continuous belts that can be spliced to any length without needing special tools or equipment for installation.

The mesh belt cover material can be customized, like nitrile, silicone, rubber and so on. Now YONGHANG mainly offer is red nitrile covered ZipLink belt, which exhibits excellent abrasion and cut resistance.It is widely used for transporting corrugated carton box on gluer machine.

- Introduction

Introduction

Description:

ZipLink uses a unique combination of traditional rubber cover materials and a structured spiral link mesh to make continuous belts that can be spliced to any length without needing special tools or equipment for installation.

Unique construction removes weak points from the splice area, making a seamless area just as strong as the rest of the belt. The increased strength not only increases performance, it gives ZipLink belts a longer lifespan than other belts using seams or fused materials.

ZipLink is a specialized conveyor belt combined structured spiral link mesh with red nitrile cover, which can be spliced to any length without tools for easy installation. ZipLink conveyor belt is widely used in folder gluer machine.

- Tool-free Splicing: No metal fasteners, vulcanization or adhesives required. The ends of the belt zip together using an integrated zipper-style joint.

- Various Top-cover Materials: The polyester monofilament spiral mesh carcass can be covered with various materials, like red nitrile, silicone or cotton.

- Reduced Downtime: ZipLink belt can be installed or repaired in minutes, significantly reducing production line downtime and improving productivity.

Features

Quickly and easily spliced without special tools or presses

No loss of strength in the splice area

Low stretch polyester monofilament carcass

High lateral stability for ease of tracking

Troughable

Manufactured in widths from 55” (1400mm) to 75” (1900mm) ± 2%

Applications

Tobacco processing

Food processing where low temperature performance, stain resistance and good product release are required

Conveying situations where minimum downtime is critical

Sanding industry

Chemical processing

Corrugated cardboard

MDF & OSB production

ZipLink conveyor belt utilize the combination of polyester monofilament spiral mesh carcass with traditional rubber cover. The unique construction allows for on-site quick and easy splicing, installation and replacement without additional tool or equipment, eliminates weak points for there is no loss of strength in the belt splice point.

The mesh belt cover material can be customized, like nitrile, silicone, rubber and so on. Now Puteken mainly offer is red nitrile covered ZipLink belt, which exhibits excellent abrasion and cut resistance.It is widely used for transporting corrugated carton box on gluer machine.

FAQ:

1.What is the main advantage of ziplink conveyor belt compared with ?

Ziplink conveyor belt major advantage is its easy replacement and installation, which greatly save workshop downtime.

2.Is the Ziplink belt joint strong, will it be weaker than traditional connections?

ZipLink connection is specially designed, tensile strength can be close to the strength of the whole belt, fully meet the needs of industrial transportation.

3.How we select the suitable ziplink belt type?

The ziplink belt selection needs to take conveyed material, working temperature, operation speed and load requirement into consideration. Puteken can provide one-to-one selection professional suggestion.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY