Rubber Block Chains

At the heart of all our conveying systems are the heavy duty YONGHANG rubber block chains

- Introduction

Introduction

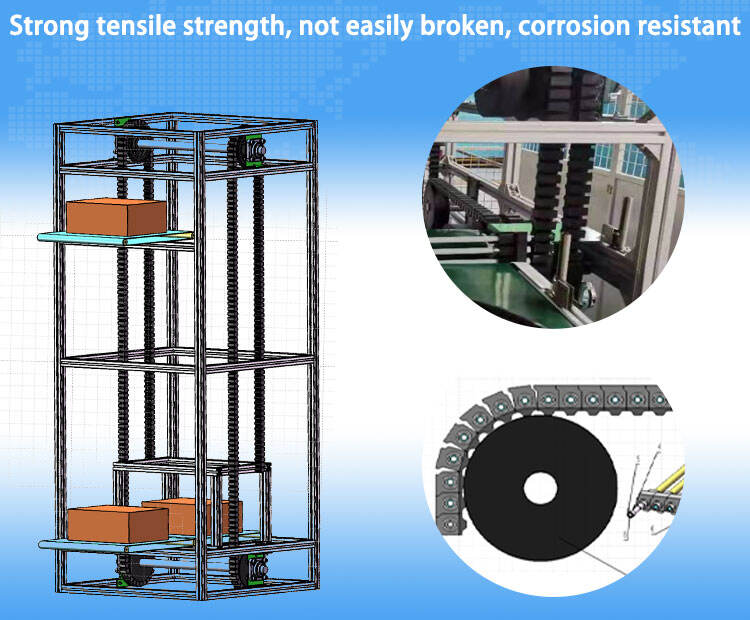

At the heart of all our conveying systems are the heavy duty YONGHANG rubber block chains. The rubber outer layer is bonded to high tensile flexible steel cables in a high-pressure vulcanizing process. Even in the most arduous of operating conditions, such as when used in an extruded rubber cooling line where the belts are continuously submerged in water, this powerful bond between the rubber carcass and inner steel cables ensures total corrosion free operation and long service life. All YONGHANG rubber block chains are manufactured in our own modern factory enabling us to ensure we can supply the correct type and style of rubber chain for each application.

- Link-free

- Silent operation

- Wear resistant

- Maintenance free

- Longevity

- Corrosion free design

- 316L Stainless Steel Wire Core

| Model | P(MM) | W(MM) | W2(MM) | H(MM) | H3(MM) | H4(MM) | D(MM) |

| NY33/32 | 33 | 32 | 23 | 36 | 12.5 | 8 | 12 |

| NY33/50 | 33 | 50 | 23 | 36 | 12.5 | 8 | 12 |

| NY43/50 | 43 | 50 | 20 | 36 | 12.5 | 8 | 12 |

| NY43/70 | 43 | 70 | 28 | 46 | 15 | 8 | 18 |

| Model | Wire(pcs) | Single-hole tension(N) | Most critical load-bearing(N) |

| NY33/32 | 7 | 150 | 111552 |

| NY33/50 | 10 | 250 | 15936 |

| NY43/50 | 10 | 250 | 15936 |

| NY43/70 | 14 | 350 | 31030 |

| Rubber Block Chain Parameter Table: | |||||||

| Model | Width(MM) | Pitch(MM) |

Wire diameter (MM) |

wires Quantity(pcs) | Most critical load-bearing(KG) | Maximum load per hole(KG) | Note |

| 33/32 | 32 | 33 | 2 | 7 | 700 | 30 | Light weight |

| 33/50 | 50 | 33 | 2 | 10 | 1000 | 50 | Standard |

| 43/50 | 50 | 43 | 2 | 10 | 1000 | 50 | Standard |

| 43/70 | 70 | 43 | 2 | 14 | 1200 | 68 | Heavy-duty |

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY