High-Precision Pneumatic-Driven Conveyor Belt Punching Machine

YONGHANG High-precision pneumatic-driven conveyor belt punching machine, specifically engineered for precision hole processing in materials such as leather, canvas, PVC, PU, and lightweight rubber conveyor belts. This equipment employs pneumatic drive and a rigid frame structure to achieve efficient punching operations while ensuring hole position accuracy and edge flatness. It serves as a critical processing device for conveyor belt manufacturing, maintenance, and accessory installation.

- Introduction

Introduction

Features:

Pneumatic drive, efficient and stable

Utilising compressed air as the power source, the punching action is swift and forceful with relatively low noise levels. It possesses inherent overload buffering properties, effectively protecting the dies.

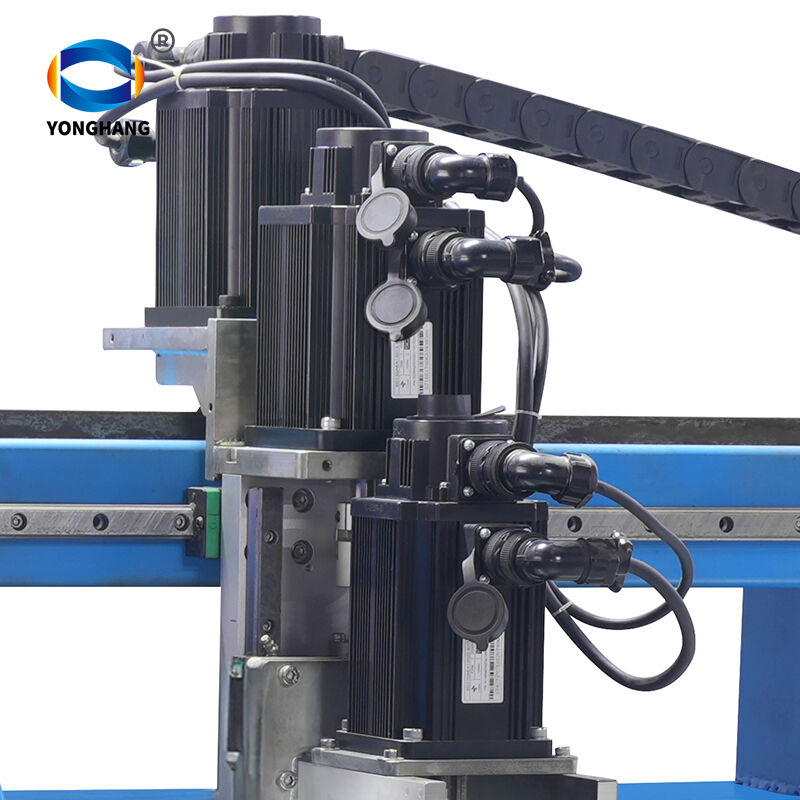

High rigidity, exceptional precision

The substantial cast iron or steel frame (approximately 500-1000kg) ensures outstanding stability during punching operations, thereby guaranteeing hole position accuracy and repeat positioning precision.

Safe and Convenient Operation

Standard dual-hand start buttons, emergency stop devices, and physical guards comply with safety regulations. Workbenches typically feature adjustable positioning stops for rapid alignment.

Versatile Tooling Compatibility

Accommodates various specifications of round, square, and special-shaped hole dies. The quick-change die mechanism flexibly adapts to diverse punching requirements.

Broad Applicability

Primarily suited for punching operations on medium-to-low hardness materials, typically within a thickness range of 1–10 mm, including fabric-reinforced conveyor belts and synthetic leather belts.

Product parameters:

| Length width height | 2460*1200*1650mm |

| Air pressure | 0.4 MPa (4 kg/cm²) |

| Power | 1250W |

YONGHANG conveyor belt punching machine offers a dependable and efficient solution for routine hole processing on standard conveyor belts, featuring pneumatic drive, robust construction, and clearly defined fundamental parameters. It strikes an ideal balance between processing capability and equipment cost, making it a practical piece of equipment for workshops undertaking standardised, batch hole-making tasks.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY