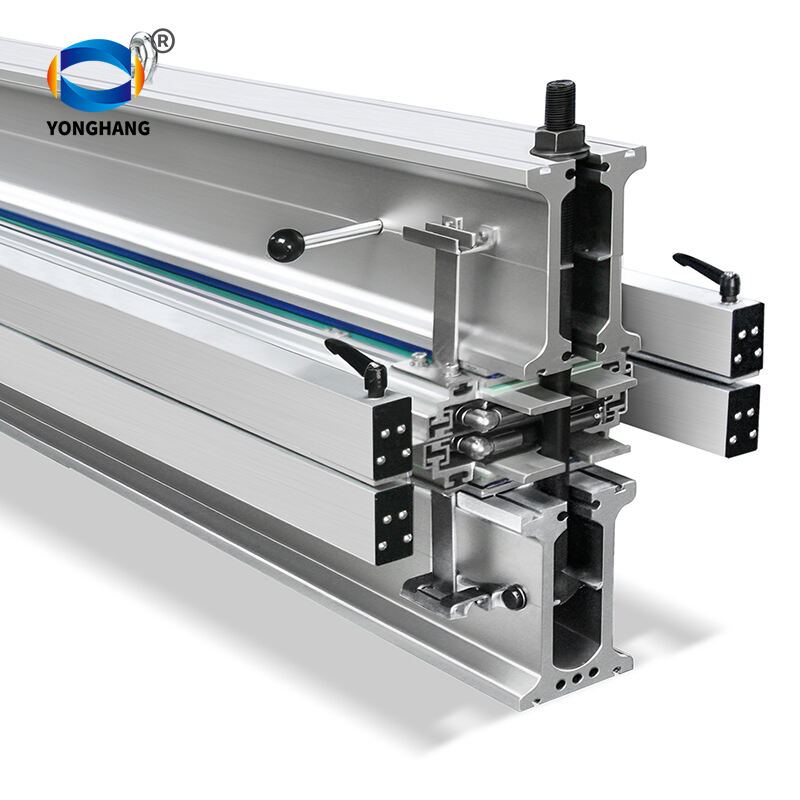

2.6 Metres Water-Cooled Conveyor Belt Heating Press Machine

The YONGHANG 2.6 Metres Water-Cooled Conveyor Belt Heating Press Machine is a specialized device for splicing conveyor belts, using high temperature,pressure, and water-cooling technology, Equipped with a water circulation cooling system, it enables rapid curing of bel oints on-siteIt is mainly used for PVC, PU, and PE conveyor belts.

- Introduction

Introduction

Features:

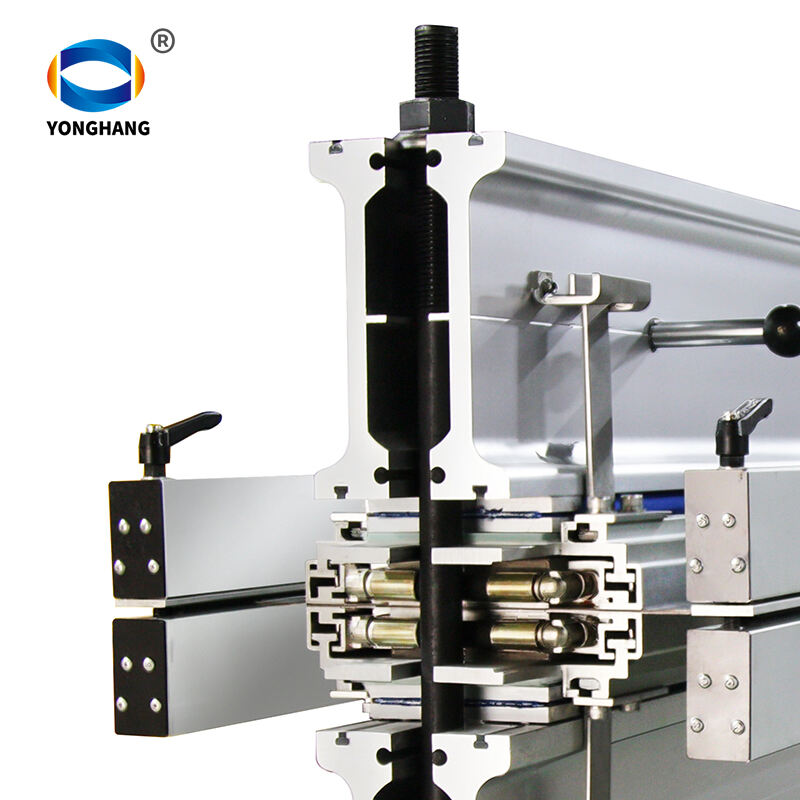

- 2.6 Metres Water-Cooled Conveyor Belt Heating Press Machine Employing hot-melt and water-cooled curing technology, this system achieves belt joint connections approaching the strength of the original material. It effectively prevents tearing and delamination during operation, ensuring the stability and safety of continuous production lines.

- The rapid water-cooling system drastically reduces the hours-long wait required for traditional joint cooling and curing, enabling swift splicing and repairs. This significantly minimises economic losses from production downtime.

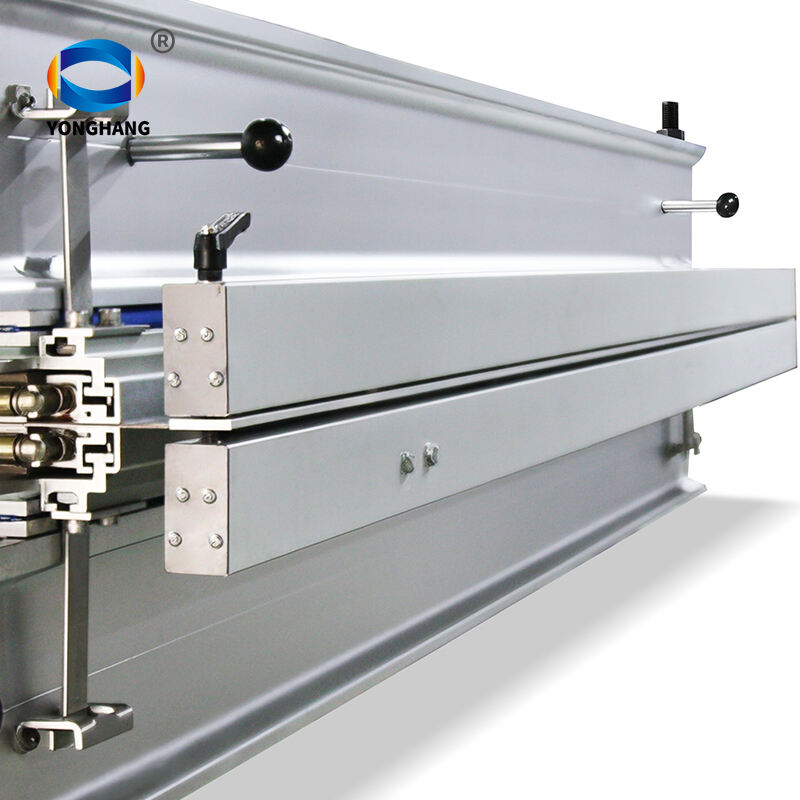

- The 2.6 Metres Water-Cooled Conveyor Belt Heating Press Machine is specifically designed for on-site splicing. It completes the entire process—from cutting and grinding to hot-melt splicing and cooling/curing—without requiring the conveyor belt to be removed and returned to the factory. This saves time and labour while offering strong emergency response capabilities.

- Process optimisation for diverse materials—including PVC, PU, and PE—ensures high-quality, highly compatible seamless splicing for all common industrial conveyor belts.

- The 2.6 Metres Water-Cooled Conveyor Belt Heating Press Machine hot-melt splicing process requires no chemical adhesives and produces no toxic volatiles. Concurrently, the joint surface remains smooth and flush without bulky overlaps, minimising material residue and misalignment while reducing equipment wear and maintenance costs.

Product parameters:

| Model | YH-S2000 | YH-S2200 | YH-S2400 | YH-S2600 | YH-S3000 | YH-S3200 | YH-S3400 | YH-S3600 | YH-S4000 |

| Effective length | 2000 mm | 2200mm | 2400mm | 2600mm | 3000mm | 3200mm | 3400mm | 3600mm | 4000mm |

| Effective heating width | 180 mm | 180 mm | 180 mm | 180mm | 180 mm | 180 mm | 180 mm | 180 mm | 180 mm |

| Mini joints length | 930mm | 930mm | 930mm | 930mm | 930mm | 930mm | 930mm | 930mm | 930mm |

| Lower beam | 150kg | 165kg | 180kg | 195kg | 225kg | 240kg | 255kg | 270kg | 300kg |

| Upper beam | 148kg | 163kg | 178kg | 193kg | 222kg | 237kg | 252kg | 266kg | 296kg |

| Bare machine weight | 298kg | 328kg | 358kg | 388kg | 447kg | 477kg | 507kg | 536kg | 596kg |

| Machine length | 2260 mm | 2460 mm | 2660 mm | 2860 mm | 3260 mm | 3460 mm | 3660 mm | 3860 mm | 4260 mm |

| Machine height | 700mm | 700mm | 700mm | 700mm | 700mm | 700mm | 700mm | 700mm | 700mm |

| Machine width | 450mm | 450mm | 450mm | 450mm | 450mm | 450mm | 450mm | 450mm | 450mm |

| Maximum pressure | 7 Bar | 7 Bar | 7 Bar | 7Bar | 7 Bar | 7 Bar | 7 Bar | 7 Bar | 7 Bar |

| Maximum temperature | 210 ˚C | 210 ˚C | 210 ˚C | 210 ˚C | 210 ˚C | 210 ˚C | 210 ˚C | 210 ˚C | 210 ˚C |

| Working voltage | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 380V |

| Wooden box size | 2700*500*750mm | 2900*500*750mm | 3100*500*750mm | 3300*500*750mm | 3700*500*750mm | 3900*500*750mm | 4100*500*750mm | 4300*500*750mm | 4700*500*750mm |

| Packing weight (including accessories) |

428kg | 464kg | 502kg | 542kg | 613kg | 650kg | 687kg | 723kg | 798kg |

| Power | 6.0KW | 6.6KW | 7.2KW | 7.8KW | 9.0KW | 9.6KW | 10.0KW | 10.4KW | 15.8kW |

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY