500~6000

Haul Off Belts

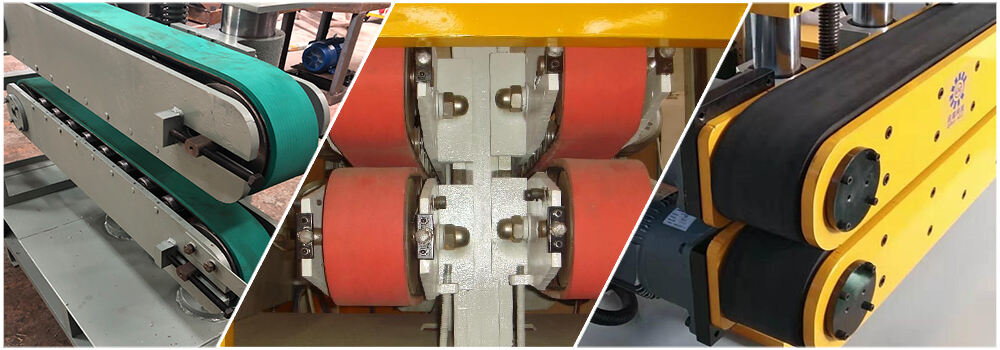

YONGHANG caterpillar belts for haul-off units of cable, wire, pipes and plastic profiles. The wide range of rubber qualities, tensile inserts and surface execution allows to fullfil at best any application requirement.

- Introduction

Introduction

YONGHANG supplies Haul-off belts for all types of extruders, including caterpillar haul-off for cables, wires, pipes and profiles.

Haul-offs” are pulley-driven parallel belts that contact opposite sides of in-process products, usually by means of rollers exerting suitable pressure for the belts to grip and haul them, with the desired controlled pulling action.

Our range includes specific combination of base belts, tensile strengths and fabrication details to meet technical requirements of variety of extrusion applications, including specific resistance, hardness, temperature, friction needs.

Please contact us direct for more information regarding your specific requirements.

Applications of Haul Off Belts:

- Manufacturing of electric cables

- Production of plastic profiles

- Production of wire cables

- Production of pipes

- Tubing

- Automotive

- Vinyl Siding

Base Belt Options

-

Timing Belt

- T2.5, T5, AT5, T10, 3M, 5M, 8M, L, XL, H, RPP

-

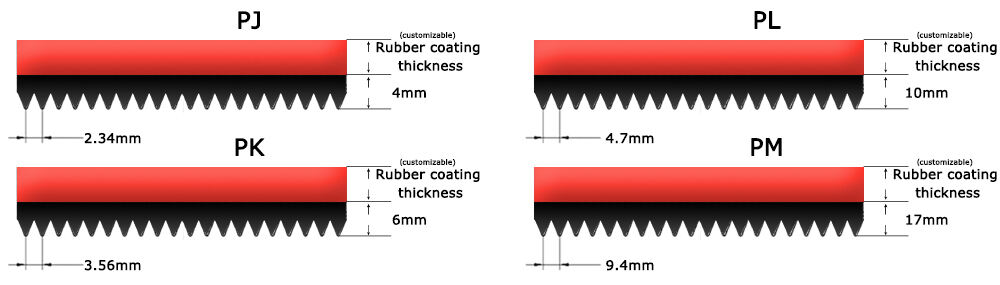

Poly V Belt

- PJ, PK, PL, PH

- Flat Belt

- Rubber

- Polyurethane

Haul off belts standard sizes:

Haul off belts commonly used PL pitch 4.7mm,suitable forall kinds of cable traction machine extrusion machine, PVC pipe shaped strip and other plastic products have high performance traction,seamless endless process,no joints,no breakage,smooth surface,strong tensile strength,wear resistance,long life,etc.hardness range 40-75 degrees,working temperature -10°C-80°C,the color can be made blue,red,green,white,black,or in the surface of the arc,V/U grooves,etc.red,green,white,black,or in the surface of the arc,V/U grooves,etc.

| Parameters | PJ | PK | PL | PM | ||

| Ribs pitch | 2.34 | 3.56 | 4.7 | 9.4 | ||

| Width | 20~400 | 20~400 | 20~400 | 20~400 | ||

| Thickness | 6~12 | 7~15 | 12~30 | 20~50 | ||

| Length | 500~6000 | 1000~6000 |

2000~ 200000 |

|||

| Material | rubber | rubber | rubber | rubber | ||

| Rupture strength | 56~60 | 116~124 | 232~248 | 532~572 | ||

| Tensile Ratio | 0.5~0.6 | 0.6~0.7 | 0.75~0.85 | 0.95~1.1 | ||

| Tensile load | 14~15 | 29~31 | 85~62 | 133~143 | ||

| Surface friction coefficient | 1~2 | 1~2 | 1~2 | 1~2 | ||

| Min.use diameter | C50 | 85 | Ø150 | C240 | ||

| Working temperature | -20~+80 | -20~+80 | -20~+80 | -20~+80 | ||

Machining:

- Perforation

- Slotting

- Grinding

- Grooving

- Tooth removal

Profiling:

Cable side

- all half-round profiles available upon request

- V grooves: 90°, 100°, 110°, 116°, 120°, 136°, 150°

- U grooves: 90°, 100°, 110°, 116°, 120°, 136°, 150°

- Various types of grooving

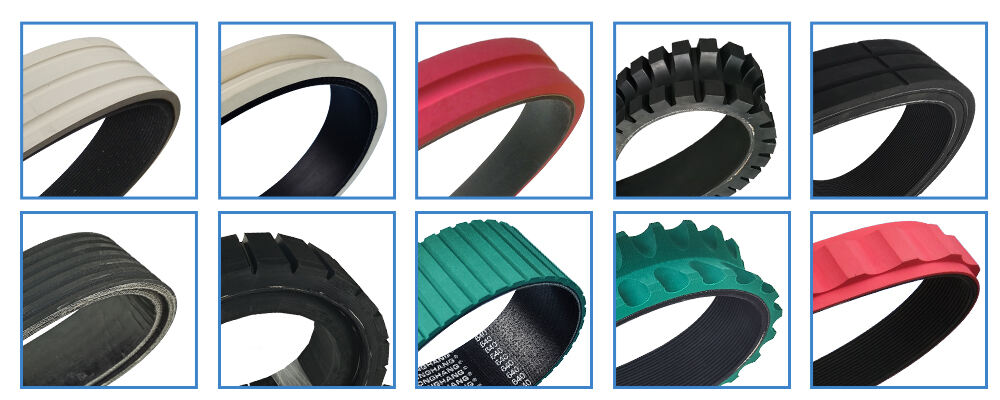

Coating:

- 40~70 Duro Shore A

- Excellent Grip

- Abrasion Resistance

- Strong Tensile Cord

- Oil Resistant (Upon Request)

- Non Marking (Upon Request)

- Color: Red, White, Black, Green, Grey, Blue, Brown

-

Materials that are fitting include:

- CRC04 Black Neoprene foam (Flexible for the belt to fit small pulleys)

- PUCC04 Microcellular Polyurethane foam

- NR40 & NR50 Tan Natural rubbers

- NR60 & NR70 Red Natural / Synthetic rubbers

- CR50 & CR60 Black Neoprene rubber

- PU65 Polyurethane elastomer

- NRF40 & NRF60 white rubber (for rigid profile; no oils and chemicals contact)

- NR40XAR Red High abrasion Natural Rubber (no oils and chemicals contact)

- PVC

- Silicone

Features of Haul Off Belts:

- Endless – No joints or splicing

- Thermal Bonding – Guards against cover delamination

- Bi-Directional – Precision ground covers ensure adaptability

- Custom Thickness

- Customized covers available

-

Covers adhere to various materials:

- Polyurethane

- Rubber

- Timing Belt

- Poly/Micro V Belt

- Flat Belt

- Banded Vee

- Plastic/Nylon

FAQ

What is haul off extrusion ?

A Haul-off is engineered to consistently pull the profiles produced during the extrusion process. YongHangBelt provides two varieties of haul-offs: belt and caterpillar.

The double belt haul-off, used in PVC profile extrusion lines, is important for pulling profiles. By employing various rubber pads on caterpillars, the haul-off can accommodate profiles of different shapes. The device also features an adjustable draw-off speed tailored to the extrusion process.

What are the different types of haul-off ?

Haul-offs are available in various types, such as Belt, Double Caterpillar and Multiple Caterpillar. Each tailored for specific product diameters and production speeds. Belt haul-offs are well-suited for cables, pipes and wires with smaller diameters, typically ranging from 10mm to 32mm, especially in scenarios requiring high-speed production.

Alternatively, bigger diameter pipes require the use of multiple caterpillar haul-offs or double caterpillar haul-offs. Selecting the right haul-off unit for your specific production line is vital to prevent potential issues and ensure seamless production.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY