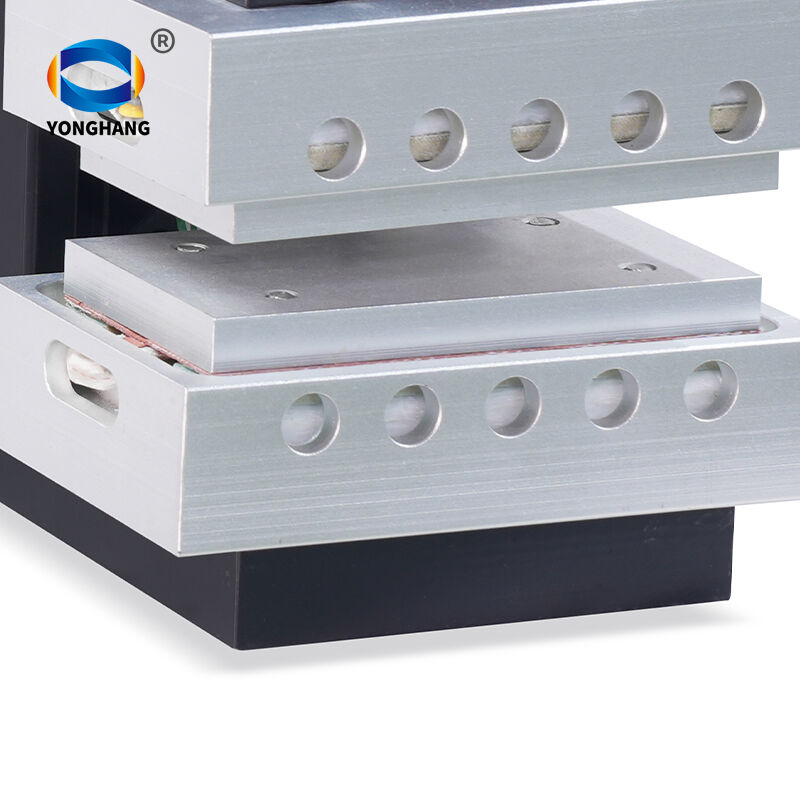

T50 Small PU Timing Belt Splicing Machine

YONGHANG compact timing belt splicing machine is a precision hot-melt device specifically engineered for on-site splicing of polyurethane timing belts. Utilising microprocessor-controlled temperature regulation and a constant-pressure system, it achieves precise alignment of the belt's tooth profile and seamless fusion, with splice strength exceeding 85% of the original belt's integrity. With a body weight under 15kg and compact dimensions, it is particularly suited for precision belt repair tasks in confined spaces, such as equipment maintenance, robotic joint transmission systems, and medical devices.

- Introduction

Introduction

Product Features:

- Toothed positioning slots compatible with multiple tooth profiles including MXL/XL/L/H/XH

- Bidirectional fine-adjustment knobs (0.02mm precision) enable three-dimensional precision positioning

- PID segmented temperature control technology, adjustable range 50-250°C

- Heating plate temperature differential ≤±1.5℃ (compliant with DIN 7337 standard)

- Automatic power cut-off for abnormal temperatures

- Screw-type constant pressure mechanism provides adjustable pressure from 0-3MPa

- Pressure holding accuracy ±0.05MPa

- Quick-release pressure module supports one-handed operation

Product parameters:

| Model | YH-T50 |

| Heating method | The upper and lower molds are heated independently |

| Size of the heating plate | 110mm*50mm |

| Heating temperature | Max 200℃ |

| Machine size | 150mm*140mm*260mm |

| Cooling time | 15—25 min |

| Temperature control box | Fully automatic control |

| Belt connection width range | Customizable templates are available |

| Weight | 12KG |

| Working voltage | 220V |

| Power | 420W |

| Shortest response | 320mm |

| Connection range | Power belts,sheet base belts,transmission belts,polyurethane synchronous belts,conveyor belts,etc |

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY