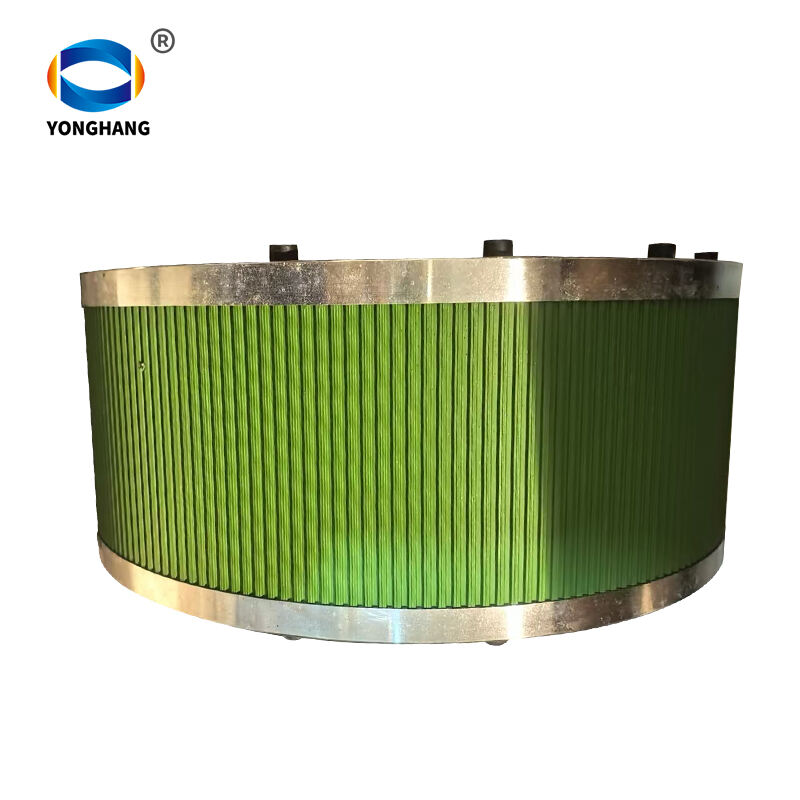

PU Timing Belt Forming Mold

YONGHANG PU timing belt forming moulds are specifically engineered for the precision manufacture of polyurethane synchronous belts. Constructed from high-strength steel with precision-machined tooth profiles, they ensure accurate belt dimensions and stable transmission. Characterised by efficient forming, extended service life, and strong adaptability, these moulds serve as the core tool in industrial production for guaranteeing timing belt quality and performance.

- Introduction

Introduction

Features of PU Timing Belt Forming Mold:

- Employing high-precision machining technology ensures accurate synchronous belt tooth profiles, delivering smooth transmission and low noise levels.

- Utilising premium mould steel or special alloys, heat-treated for enhanced strength, significantly extends die service life.

- Optimised structural design guarantees uniform polyurethane material filling and rapid curing, boosting production efficiency.

- The mould exhibits high overall rigidity, withstanding high forming pressures without deformation during prolonged use, thereby guaranteeing product consistency.

- Customisable specifications (including trapezoidal teeth, circular arc teeth) and dimensions are available to accommodate various pulley models.

PU Timing Belt Forming Mold Size :

Model |

Size |

|||

T20/AT20 |

430/100 |

|||

T10/AT10 |

430/100 |

|||

T5/AT5 |

430/100 |

|||

XL/L/H/XH |

430/100 |

|||

3M/5M/8M/14M |

430/100 |

|||

S3M S5M S8M S14M |

430/100 |

|||

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY