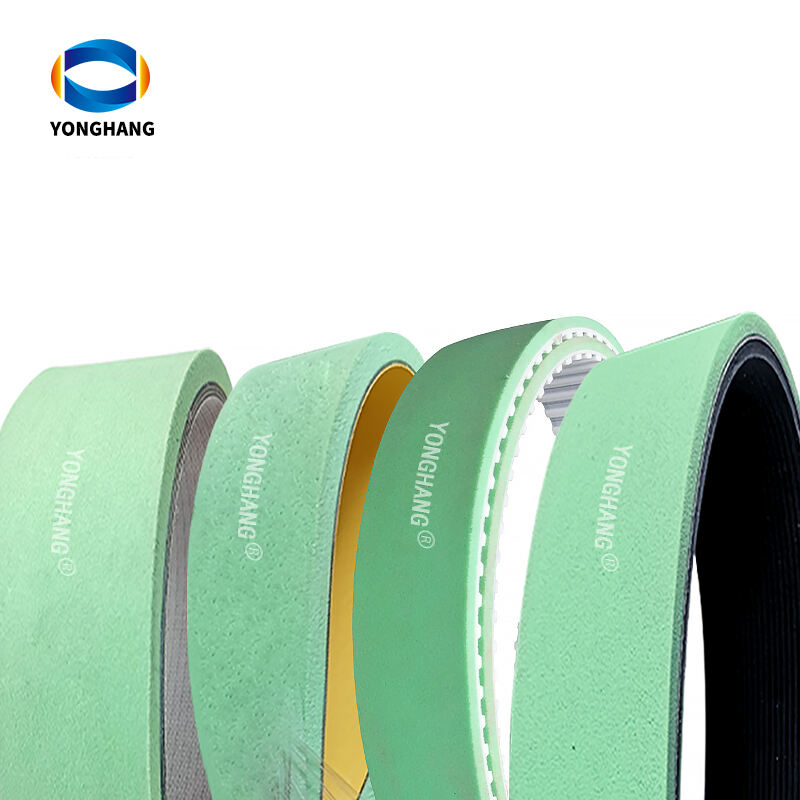

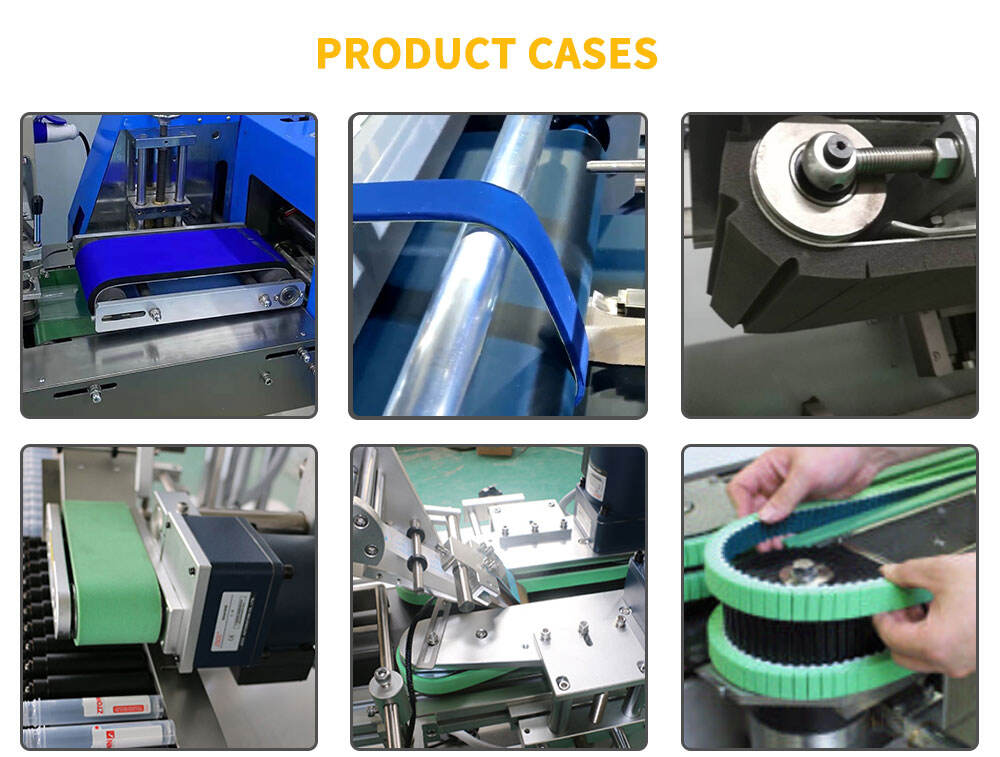

Our modern machinery,which mainly contains in house developed machines,we are able to carry out almost all activities relating to the processing and finishing of FoamTransmission belts.Ask our specialists about The wide range of machining options,take advantage of our many years of experience in the field of machined Foam Transmission belts.

Of course, we also have these sheet materials for sale. If you are a producer or distributor of industrial belts and need to purchase sheet materials from China for your own processing, we can offer you the best price and samples

Application of EVA material

Finished products made of EVA material have good flexibility, shockproof, anti-slip, strong pressure resistance, usually used in beer and beauty products production line, glass bottle transmission, labeling machine, medical hose production line and so on.

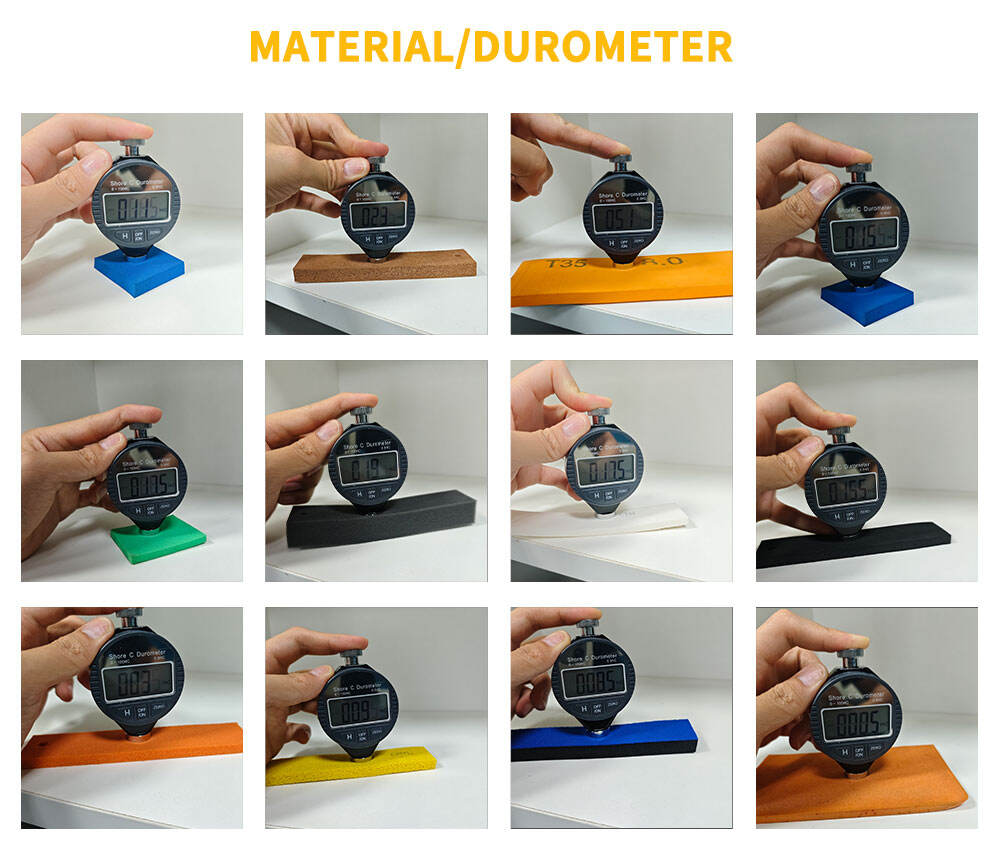

Characteristics of EVA material

1.Shock resistance: high resilience and tensile strength, strong toughness and good shockproof/cushioning performance.

2.Environmental protection: EVA raw material itself is non-toxic environmentally friendly materials, biodegradable

3.Corrosion resistance: resistant to seawater, grease, acid, alkali and other chemicals corrosion, antibacterial, non-toxic, tasteless, non-polluting.

4.Thermal insulation: EVA has excellent thermal insulation and cold resistance, can withstand severe cold and exposure to the sun.

5.Odorless: EVA is an environmentally friendly odorless material, also suitable for a variety of products to do the packaging drive belt

Production of EVA materials

Provide all kinds of EVA foam materials, including EVA sheets, rolls, sponges, high foam, adhesive backing, etc., EVA foam using environmentally friendly and non-toxic raw materials, according to your needs to provide you with from 25°C - 75°C different hardness and a variety of colors of EVA materials.

all Finished products and processes are 100% inspected, every month with the quality reviewing meeting to review problems and This is the quality control process during the Production process. so we just make sure every size of the Foam Transmission Belt is on the right According to the drawing, YONGHANG has 5 inspectors,1 for the incoming material inspection,3 inline inspectors for the production steps, and 1 inspector for the final products. All raw materials incoming are inspected, such as Sponge,Foam,Rubber and PU , Stainless steel raw materials, Nut and so on. Each step like cutting,Bonding,grinding,Slotting,drilling and so on ,reviewing meeting to review problems and make plans with tools, such as 8D reports,5WHY 3W2H and so on.

This is the quality control process of the raw materials. We have to ensure the material is the right one, and also the right thickness. The right materials grade.This is the quality control in the Before packaging. So our workers will ensure the size and also the angles are on the right way. According to the drawing, this quality control process is very important before the Production process. We can just make every process is right, and every detail is just according to your drawing, this quality control process is before the bonding.

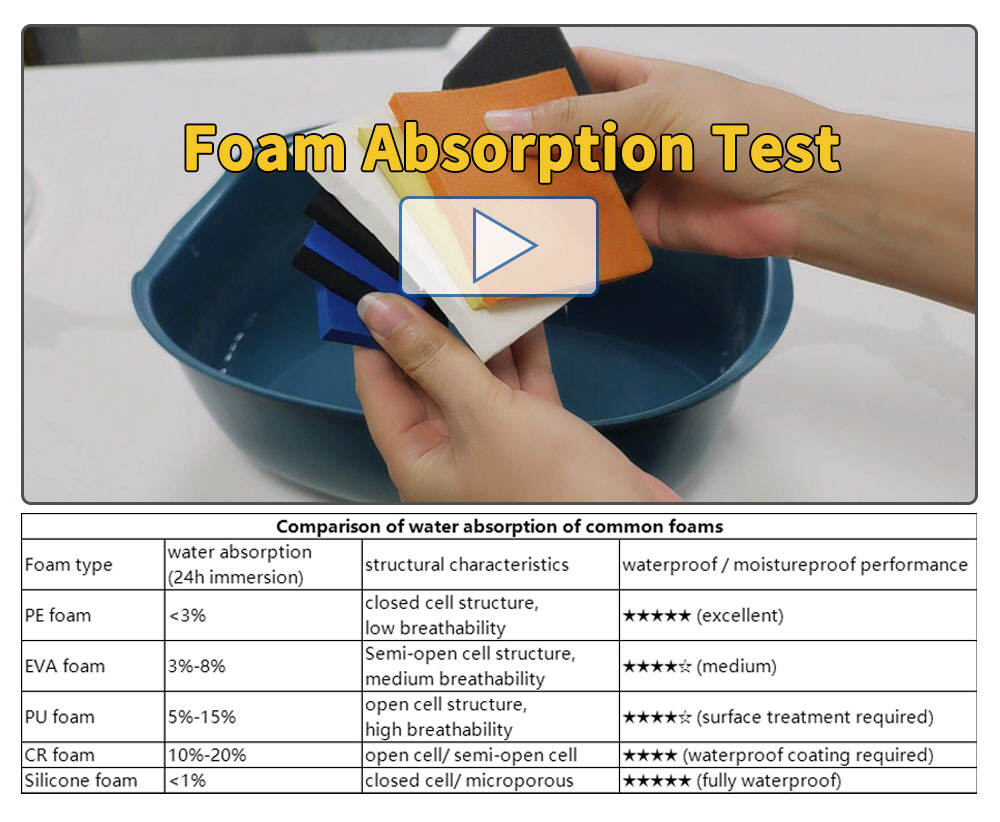

This is the quality control process for the final products. This process is very important before the order packaging, so we just make sure every detail including the size the thickness, the accessories, the drawing the ceiling system, and the whole structure is really 100% based on the drawing, and also we have quality control report for every Foam Transmission belts you make, so we just make ensure the holes and the materials, and the thickness, Density,hardness , The sheet material of the base band,Water absorption performance, all the accessories is on the right size and right requirement based on your order.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY