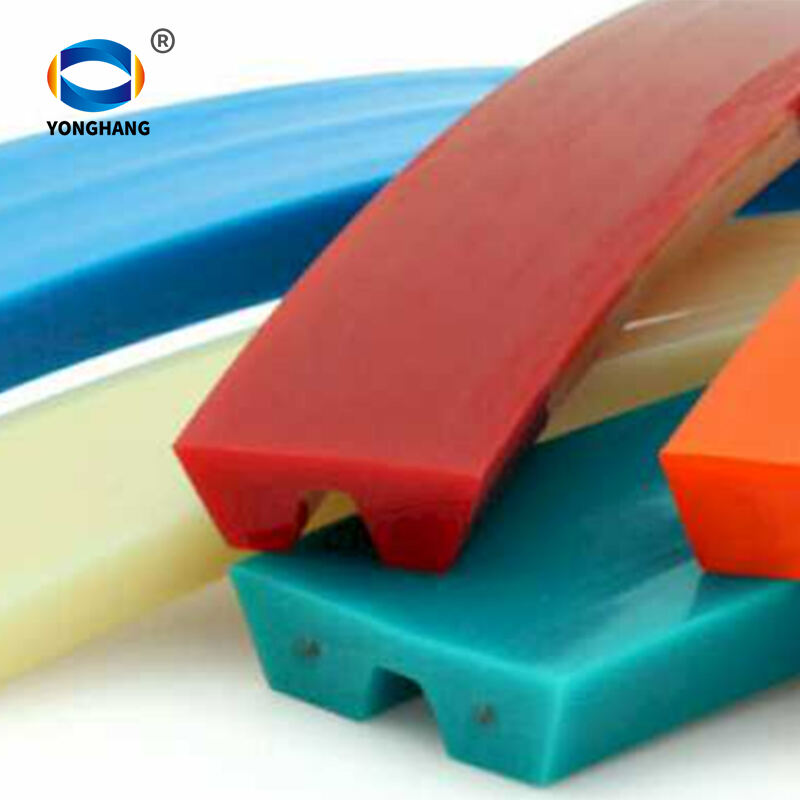

How to Easily Select, Install, and Maintain PU V-Belts to Avoid Common Issues?

The root cause of your equipment shutting down unexpectedly is often that unassuming drive belt. For those of you with machinery and equipment operating often, the ability to select and service PU V-belts will be the key skill to maintaining smooth production and minimal downtime due to unexpected equipment failures. This guide will teach you how to deal with PU V-belts by utilizing the clearest language available.

I. Identify Your Needs: Is PU V-belt right for your equipment?

Before buying a PU V-belt, do a brief review:

If your equipment: Requires consistent cleaning, subject to oil contamination, operates in a humid environment, does not want to see a belt replaced often, to where the belt requires high synchronous transmission--

Then PU V-belts are right for your equipment.

If your equipment: Concedes consistent high heat (greater than 80 °C), or will be subject to strong acids/alkalis.

Then your equipment may qualify for different ideas/materials - you may want to consult with a specialist.

II. Four Steps to Select a PU V-Belt

Keep in mind the four characters, “T-L-H-E” (Type, Length, Pulley, Environment):

1. Identify Type (型号): Remove the old belt and check its top width and height to match the model code (e.g., the common model A, B or smaller models Z/SPZ). If the old belt is no good, you can use calipers to measure.

2. Measure length (长): The inner circumference is the nominal size of the PU V-belt. You should take a tape measure and wrap it snugly around the inner edge, and now you have the measurement. If the measurement is 1000 mm, then the model is PU-A-1000 (Note: One standard may refer to the outer circumference instead.)

3. Examining the Pulley grooves (轮): Prior to installation and not after, always check the wear condition of the pulley grooves. A worn pulley with “sharp grooves” will quickly damage for an expensive new PU belt like a file. If severe wear is present, sometime it is prudent to just replace all the pulleys.

- Looking at the environment (Queen I): Confirm if the operating environment has specifications for chemicals that may harm or weaken the PU. PU polymers have good oil resistance, but even the normal weekly ones may require special considerations.

III. Installation and Tensioning: Avoid Force!

Correct Installation: The biggest mistake is forcing the belt on with tools like screwdrivers! This instantly damages the internal tensile layer, creating a risk for premature failure. The correct method is: Loosen the motor base adjustment bolts to reduce the center distance between pulleys. Gently slide the belt onto the pulleys, then readjust the center distance to achieve proper tension.

Tension Adjustment:

Too loose tension → Slippage, overheating, accelerated wear; Excessive tension → Excessive bearing load, high energy consumption, excessive belt stress.

Simple Method: Press the belt at the midpoint between the pulleys with your thumb. The ideal deflection should be approximately 1.6% of the belt span (center distance). (For example, with a center distance of 500mm, the deflection should be about 8mm.) The belt should feel taut with appropriate elasticity.

Following the tension standards provided by the equipment manufacturer is best practice.

IV. Routine Maintenance and Troubleshooting

Regular Inspection: Conduct monthly routine checks for cracks, back wear, sidewall aging, or edge peeling.

Batch Replacement: In multi-belt drive systems, replace all belts even if only one is damaged. Uneven load distribution due to length differences between new and old belts will cause rapid failure of the new belts.

Maintain Cleanliness: Promptly remove oil, grease, and dust from belts and pulleys to prevent slippage and corrosion.

Proper Storage: Store spare belts in a cool, dry location away from direct sunlight, heat sources, and ozone sources.

>>Click "YONGHANG® timing belts" for more information about our products!

YONGHANG® Transmission Belt With more than 20 years of rich experience in the industry, The Company integrates research and development, production and customization, ODM&OEM Service, CE RoHs FDA ISO9001 Certification, R&d Centers, with more than 10,000m²+ factory, Molds More than 50+ sets of precision equipment, More than 8000+ sets of Molds, professional technical research and development team, precision manufacturing, providing one-stop high-quality transmission products customization service! Welcome to www.yonghangbelt.com for more information! Article copyright: YONGHANG® Transmission Belt, please specify the source, thank you for your cooperation!

Please contact us direct for more information regarding your specific requirements.

URL:http://www.yonghangbelt.com

Whatapp&wechat:+ 0086 13725100582

Email :[email protected]

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY