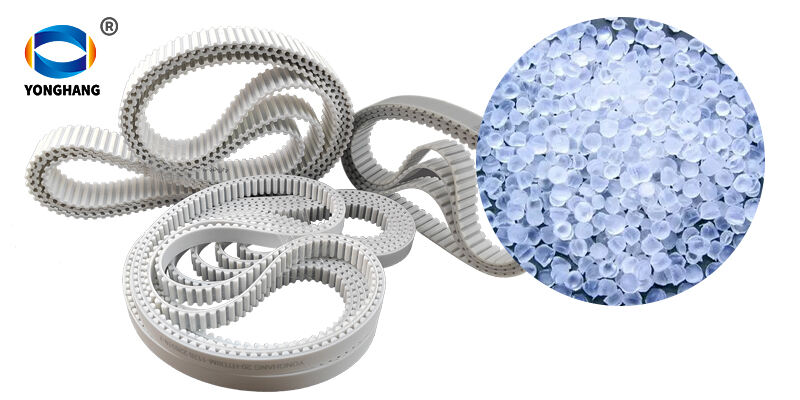

How Material Quality Determines PU Timing Belt Longevity

Key material properties affecting durability of PU timing belts

PU timing belt longevity depends mainly on three key material characteristics: how strong they stay under tension, their ability to resist wear, and how stable they remain when exposed to chemicals. Premium quality polyurethane keeps around 85 percent of its original tensile strength even after over 100 thousand bending cycles according to ASTM D412-23 standards. This makes it perform about three times better than regular rubber options in those quick wear tests we run in labs. Belt hardness matters too. Those with Shore A ratings above 95 tend to stick around about 40% longer when used in situations where there's lots of torque involved compared to the softer materials available.

Material composition significantly influences performance, as demonstrated below:

| Property | Virgin PU | Recycled PU | Nylon-Reinforced PU |

|---|---|---|---|

| Modulus of Elasticity | 35 MPa | 28 MPa | 52 MPa |

| Tear Resistance | 85 kN/m | 60 kN/m | 110 kN/m |

These metrics highlight the structural advantages of virgin and reinforced materials in demanding mechanical systems.

Virgin polyurethane vs. recycled regrind: Performance and longevity trade-offs

Using recycled regrind can cut material expenses somewhere around 15 to 20 percent, but there's a catch when it comes to how well things hold up over time. The problem lies in those inconsistent polymer chains which actually speed up the process of fatigue failure. Take a look at what happens after about 5,000 hours of operation. Virgin PU belts still have roughly 92% of their original strength left, whereas belts made with 30% regrind only manage around 78% according to research published in the Polymer Engineering Journal last year. And this difference gets even bigger when materials are exposed to harsh chemicals. Virgin PU stays dimensionally stable for almost 2 and a half times longer than its recycled counterparts do under these conditions. Makes sense why many manufacturers stick with virgin materials despite higher upfront costs.

For mission-critical applications such as medical devices or precision automation, the use of virgin polyurethane ensures consistent mechanical behavior and extended service life.

Extruded vs. injection-molded construction: Impact on belt strength and consistency

The extrusion process creates seamless PU timing belts that typically have around 0.2 mm variation in dimensions, which makes these belts great for applications where precision matters, such as in CNC machines. On the flip side, injection molding can produce more complicated tooth shapes but tends to leave behind weld lines that actually weaken the belt's strength by roughly 18 to 22 percent according to ASTM standards. Because so many automotive and industrial setups require tight tolerances of plus or minus 0.05 mm, we're seeing an increasing number of specifications calling for co-extruded belts reinforced with carbon fiber. These reinforced versions stretch less than 0.01% even when subjected to maximum loads, something that regular belts just cant match.

This shift reflects an industry preference for extrusion-based methods when reliability and dimensional precision are paramount.

Advanced Construction Techniques for Durable PU Timing Belts

Welding Methods and Joint Integrity in Endless PU Timing Belts

The strength of the joints matters a lot for those endless PU timing belts. When it comes to making them last, ultrasonic welding and hot knife methods tend to give the best results overall. Studies show that when these joints are properly fused, they hold about 95 to almost 100 percent of what the belt was originally rated for in terms of tension before breaking (Polymer Engineering Journal had some good data on this back in 2023). This means there's much less chance of the belt giving out early in applications where lots of torque is involved. Most top manufacturers have figured this out and now use sophisticated welding approaches to create connections that just keep working through all that repeated stress without developing cracks over time.

These processes are especially vital in automated production lines where downtime from belt rupture can disrupt entire operations.

Role of Precision Molding in Minimizing Weak Points and Wear

When it comes to polyurethane flow control, precision injection molding keeps things really tight within about 0.02 mm tolerance range. This helps get rid of those pesky air pockets and uneven curing spots that often plague regular extrusion methods. According to some research from ASME's Tribology department back in 2022, this kind of fine tuning actually cuts down on surface roughness by around 40%. And smoother surfaces mean less friction when these parts are running, so they don't generate as much heat while operating. The end effect? Belts made with this precise molding technique tend to last longer since they suffer from less thermal breakdown and general wear throughout their service life.

Manufacturers combining precision molding with optimized material selection achieve service intervals that exceed industry averages by 15–20%, particularly in high-accuracy sectors like packaging and CNC machining.

Environmental Resistance: Matching PU Belt Materials to Operating Conditions

Oil-Resistant, Food-Grade, and Anti-Static PU Timing Belt Variants

PU material formulations specifically designed for tough conditions deliver dependable results where standard options would fail. Belts resistant to oil maintain around 93% of their original strength even after sitting in petroleum products for over 1,000 hours according to recent testing data from material compatibility studies. These properties make them ideal choices for car manufacturing lines and heavy industrial equipment. When it comes to food production facilities, there are special versions approved under FDA regulations that stand up against enzyme activity from milk proteins or meat juices during processing operations. In dangerous workspaces like flour mills or chemical factories, manufacturers turn to anti-static belt designs with electrical resistance measurements under 10^8 ohms. This helps prevent sparks that could ignite flammable dust or vapors in these high risk environments.

Selecting the appropriate variant ensures both safety and longevity across diverse operational contexts.

Impact of Contaminants Like Grease, Chemicals, and Moisture on Belt Performance

Industrial contaminants degrade PU timing belts through distinct mechanisms:

| Contaminant | Effect | Performance Loss* |

|---|---|---|

| Grease/Oils | Plasticizer leaching | 40–60% elasticity reduction |

| Acids/Alkalis | Hydrolysis attacks urethane bonds | Up to 70% tensile loss |

| Water Ingress | Swelling (>3% volume change) | 25% pitch accuracy decline |

*Based on 2024 Chemical Resistance Study of 12 PU compounds

To prevent swelling and loss of dimensional control, belts operating in wet environments should have water absorption rates below 1.5%.

Protective Coatings (e.g., Teflon, Silicone) for Enhanced Durability and Cleanability

Applying 50–200 μm protective coatings enhances belt resilience in extreme conditions:

- Teflon®: Reduces coefficient of friction by 65% in high-speed packaging lines

- Silicone: Operates reliably from -60°C to 230°C, ideal for bakery ovens

- Abrasion-Resistant Topcoats: Reduce groove wear by 80% in mining conveyors (2023 Coating Efficacy Trials)

These treatments support single-pass CIP cleaning in hygienic environments while maintaining over 95% surface coverage after 5,000 cycles, improving both cleanliness and service life.

Maintenance Strategies to Maximize Service Life of PU Timing Belts

Critical Preventive Practices: Proper Alignment, Tension Control, and Guarding

When PU timing belts aren't properly aligned, they tend to wear out about 27% faster than those that are correctly positioned according to a study published by Industrial Transmission in 2023. Getting the alignment right helps reduce wear along the edges of the belt. Keeping the tension within the recommended range of around 4 to 6% elongation stops the teeth from getting damaged. A good quality tension gauge with about +/- 2% accuracy makes all the difference here. If belts are too loose, they'll just slip instead of driving properly. But if they're too tight, internal cracks can form over time. Installing protective guards around the belts adds another layer of protection against things like dust and oil splatter, which actually contribute to about one third of premature belt failures we see in the field.

Implementing these practices forms the foundation of a proactive maintenance strategy.

Effective Cleaning Techniques for PU Timing Belts Without Causing Damage

For cleaning food grade or chemically resistant PU belts, stick to pH neutral solutions around the 6.5 to 7.5 range and use those lint free cloths everyone recommends. Don't go crazy with steam jets hotter than 140 degrees Fahrenheit or 60 Celsius either since they can really mess things up. And absolutely skip acetone based solvents because they eat away at polyurethane over time. Most technicians swear by 70 percent isopropyl alcohol for getting rid of stubborn grease while keeping the belt structure intact. Something about that solution just works better in practice than what's written in manuals. When doing maintenance rounds, remember to vary where you clean on each belt instead of going back over the same spots again and again. This helps distribute wear more evenly across the surface.

Proper cleaning preserves surface quality and prevents premature aging.

Common Maintenance Mistakes That Shorten PU Belt Lifespan

- Improper Storage: Coiling belts tighter than 12x their diameter causes permanent curvature

- Mixed Cleaning Chemicals: Combining acidic and alkaline cleaners creates corrosive residues

- Delayed Replacement: Running belts with >3 mm tooth wear risks catastrophic drive failure

- Over-Lubrication: Applying grease to self-lubricating belts attracts debris, accelerating wear

In addition, regular thermal imaging inspections can detect hidden misalignment issues before they lead to failure, offering a non-invasive method to monitor belt health.

FAQ Section

What is the main advantage of using virgin polyurethane over recycled materials for timing belts?

Virgin polyurethane maintains higher dimensional stability and retains more tensile strength compared to recycled materials, making it more suitable for mission-critical applications.

How does precision molding impact the longevity of PU timing belts?

Precision molding reduces surface roughness and eliminates weaknesses caused by air pockets or uneven curing, resulting in less friction, heat generation, and wear, thereby extending belt life.

Why are protective coatings important for PU timing belts?

Protective coatings like Teflon and silicone enhance durability by reducing friction, withstand extreme temperatures, and support effortless cleaning, ensuring prolonged belt performance.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY