In modern manufacturing and logistics, conveyor systems play a pivotal role in ensuring efficiency and productivity.

Among the various components that contribute to the optimal performance of these systems, timing belts with cleats have emerged as a game-changer. This article delves into how these specialized belts enhance conveyor systems, focusing on their design, functionality, and benefits.

Understanding Timing Belts with Cleats

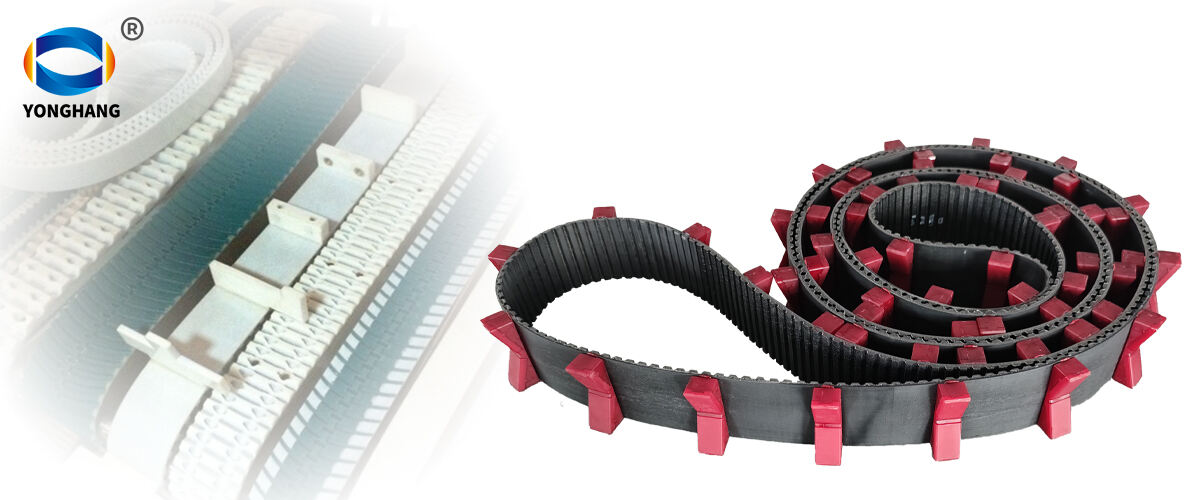

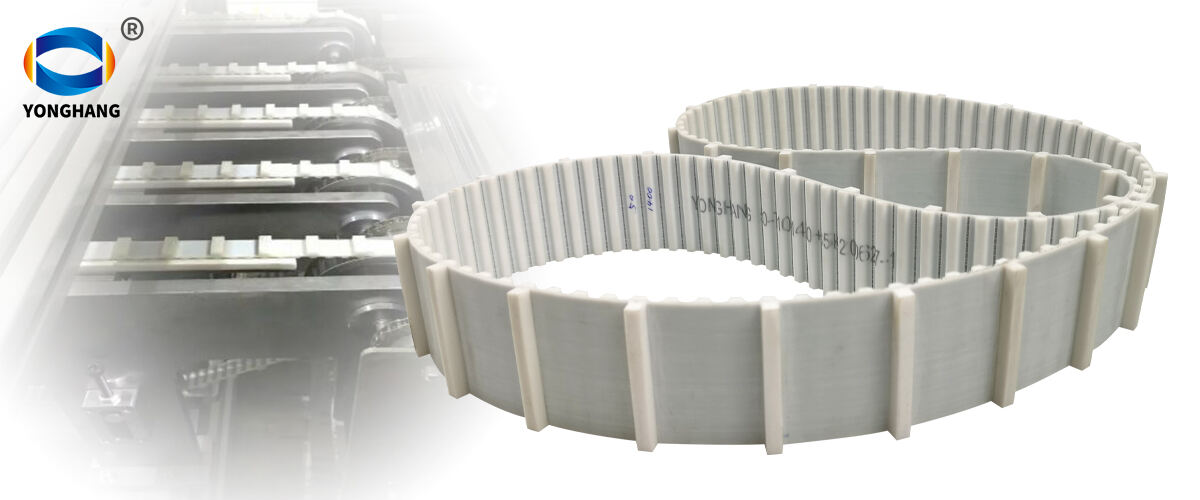

Timing belts are essential components in many mechanical systems, designed to transmit power between rotating shafts. When equipped with cleats, these belts offer additional advantages, particularly in conveyor applications. Cleats are raised sections on the belt surface that provide increased grip and stability for the transported materials. This feature is particularly beneficial when dealing with inclined or vertical movements, where traditional flat belts may struggle to maintain the load.

The Advantages of Using Cleated Timing Belts

One of the primary benefits of using timing belts with cleats is their ability to secure loads during transit. This is crucial in industries such as food processing, automotive, and packaging, where product integrity must be maintained. The cleats prevent items from slipping or rolling off the conveyor, ensuring a smoother and safer operation. Furthermore, the design of these belts allows for precise positioning of products, which is vital in automated assembly lines.

Another significant advantage is the reduction of wear and tear on both the belt and the conveyor system. Cleated timing belts are typically made from durable materials that withstand harsh operating conditions. This durability not only extends the lifespan of the belts but also reduces maintenance costs and downtime, allowing businesses to operate more efficiently.

Applications in Various Industries

Timing belts with cleats are versatile and can be found in a wide range of applications across different industries. In the food industry, for example, these belts are used to transport items such as fruits, vegetables, and packaged goods. The cleats ensure that products remain secure, reducing the risk of contamination and spoilage. In the automotive sector, they are employed in assembly lines where precise movement is essential for the assembly of complex components.

In addition to traditional manufacturing environments, these belts are increasingly being utilized in automated warehousing and distribution centers. The rise of e-commerce has led to a demand for efficient sorting and packaging systems, where timing belts with cleats play a crucial role in moving products through various stages of processing.

Future Trends in Conveyor Technology

As industries continue to evolve, so do the technologies that support them. The future of conveyor systems will likely see further innovations in timing belt design and functionality. One trend is the integration of smart technologies, such as sensors and IoT devices, which can monitor belt performance in real-time. This data-driven approach allows for predictive maintenance, enhancing operational efficiency and reducing unexpected failures.

Moreover, as sustainability becomes a priority, manufacturers are exploring eco-friendly materials for timing belts with cleats. These advancements not only contribute to reduced environmental impact but also cater to the growing consumer demand for sustainable practices in production.

In conclusion, timing belts with cleats are an essential component of modern conveyor systems, providing enhanced stability, reduced wear, and versatility across various industries. As technology continues to advance, these belts will play a critical role in shaping the future of manufacturing and logistics, ensuring that businesses remain competitive in an ever-evolving market.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY