In the modern food production landscape, the efficiency and reliability of machinery play a crucial role.

One of the often-overlooked components in this equation is the flour mill belt. These belts are essential for the seamless operation of flour mills, impacting not only the production speed but also the quality of the flour produced. This article delves into the various types of flour mill belts, their applications, maintenance practices, and the latest industry trends.

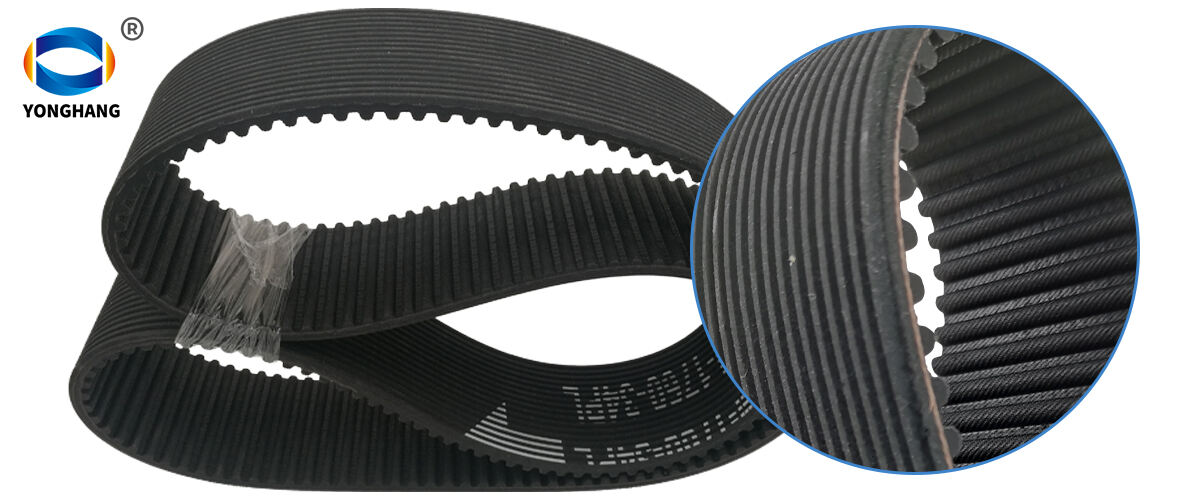

Flour mill belts come in various forms, including flat belts, V-belts, and timing belts.

Each type has its unique advantages depending on the specific requirements of the milling process. Flat belts, for instance, are widely used due to their ability to transmit power efficiently over long distances. They are particularly advantageous in large-scale operations where space and distance can be a challenge. V-belts, on the other hand, are known for their grip and stability, making them ideal for high-torque applications. Timing belts are used in scenarios where precise timing is critical, ensuring that the machinery operates in perfect sync.

The choice of a flour mill belt should be influenced by several factors, including the type of grain being processed, the milling technique employed, and the operational environment.

For instance, a mill that processes wheat may require a different belt compared to one that handles corn or rye.

Additionally, the environment in which the mill operates—such as humidity levels and temperature—can affect the performance and longevity of the belts. Therefore, manufacturers must consider these variables when selecting the appropriate belt for their operations.

Maintenance of flour mill belts is another crucial aspect that directly impacts production efficiency.

Regular inspections for wear and tear, proper tensioning, and alignment checks are essential practices that can prevent unexpected downtimes. Moreover, the use of high-quality materials in belt construction can significantly enhance durability and reduce maintenance costs. Companies should invest in training their personnel on best maintenance practices to prolong the life of their flour mill belts and maintain optimal production levels.

As the food production industry evolves, so do the technologies associated with flour milling.

Innovations such as the use of synthetic materials in belt manufacturing are gaining traction due to their superior performance and longevity. Additionally, advancements in monitoring technology allow for real-time tracking of belt performance, enabling predictive maintenance and minimizing downtime. These trends indicate a shift towards more efficient and sustainable practices in food production, aligning with the industry's broader goals of reducing waste and improving resource management.

In conclusion, flour mill belts are a critical component of the food production process, influencing both efficiency and quality.

By understanding the various types of belts available, their specific applications, and the importance of maintenance, manufacturers can make informed decisions that enhance their operations. As the industry continues to innovate, staying abreast of these developments will be vital for companies looking to maintain a competitive edge in the market.

Table of Contents

- In the modern food production landscape, the efficiency and reliability of machinery play a crucial role.

- Flour mill belts come in various forms, including flat belts, V-belts, and timing belts.

- The choice of a flour mill belt should be influenced by several factors, including the type of grain being processed, the milling technique employed, and the operational environment.

- Maintenance of flour mill belts is another crucial aspect that directly impacts production efficiency.

- As the food production industry evolves, so do the technologies associated with flour milling.

- In conclusion, flour mill belts are a critical component of the food production process, influencing both efficiency and quality.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY