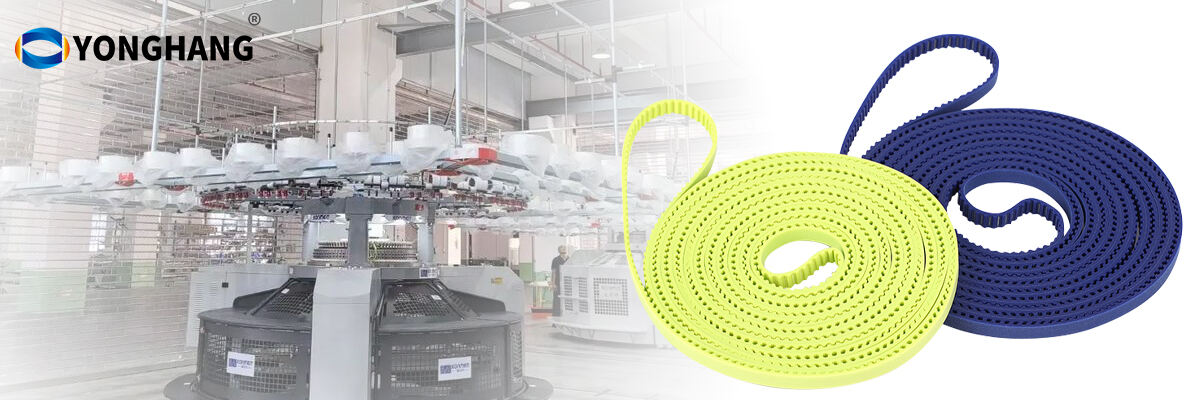

A must see for textile mills! How to choose knitting machine belt correctly?

Textile big round machine often would have long running time, and the transmission system would be inevitably wear and tear, wherein a knitting machine belt replacement and selection affected production efficiency directly. Wrong belt selection may include equipment failure, fabric defects and downtime losses. The following article will analyze on how to choose knitting machine belt correctly to have a worry free production.

1. Key parameters of the knitting machine belt: Specify the right parameters, don't be the "belt is not the right wheel".

Tooth type: tooth type must match—TT5 means 5mm tooth pitch, must be matched exactly with pulley tooth groove, otherwise it is easy to slip or wear.

Width: width for load rating (common values 15mm - 50mm widths), narrower means easier to break, while wider adds friction and energy with no benefit.

Length: belt circumference = number of teeth × 5mm, the installation should ensure that tension is adequate (a tensionometer test is available).

2. Material: the common defects of poor quality belts.

Polyurethane deterioration: poor quality materials are easily hardened and cracked with an assumed life of 3~6 months.

Steel wire core cutting corners: some belts at the low price point indicate a nylon wire core which has low strength and is prone to breaking.

3. Maintenance Replacing Knitting Machine Belts

Regular inspections: Every month, check the belt tension, wear and tear -, and adjust or replace before reaching 125% stretched limit.

Correct installation: Do not use sharp implements to pry, as this could cause damage to steel wire layer.

Storage recommendations: in a cool and dry place away from oils and do not place in direct sunlight.

4. Why use our knitting machine belts?

12 years of industry experience: accurately match textile big round machines needs - provide a high precision and longevity belt.

Countless specifications available: allow for custom cut lengths and widths or meet the needs of other models.

Quality assurance: imported polyurethane + high carbon steel wire - ensure transmission stability and reduced costs from down time.

>>Click "YONGHANG® timing belts" for more information about our products!

YONGHANG® Transmission Belt With more than 20 years of rich experience in the industry, The Company integrates research and development, production and customization, ODM&OEM Service, CE RoHs FDA ISO9001 Certification, R&d Centers, with more than 10,000m²+ factory, Molds More than 50+ sets of precision equipment, More than 8000+ sets of Molds, professional technical research and development team, precision manufacturing, providing one-stop high-quality transmission products customization service! Welcome to www.yonghangbelt.com for more information! Article copyright: YONGHANG® Transmission Belt, please specify the source, thank you for your cooperation!

Please contact us direct for more information regarding your specific requirements.

URL:http://www.yonghangbelt.com

Whatapp&wechat:+ 0086 13725100582

Email :[email protected]

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY