What Is a Timing Belt with Cleats?

A belt of synchronous drive with cleats is a type of mechanical power transmission element that has oblong raised rubber or polyurethane protrusions (cleats) oriented at an angle to the surface of the belt. A cleated timing belt differs from a standard timing in that while it provides synchronous drive it also aids in the positive displacement of material—allowing for use on inclines up to 45° or when gravity is working against material retention.

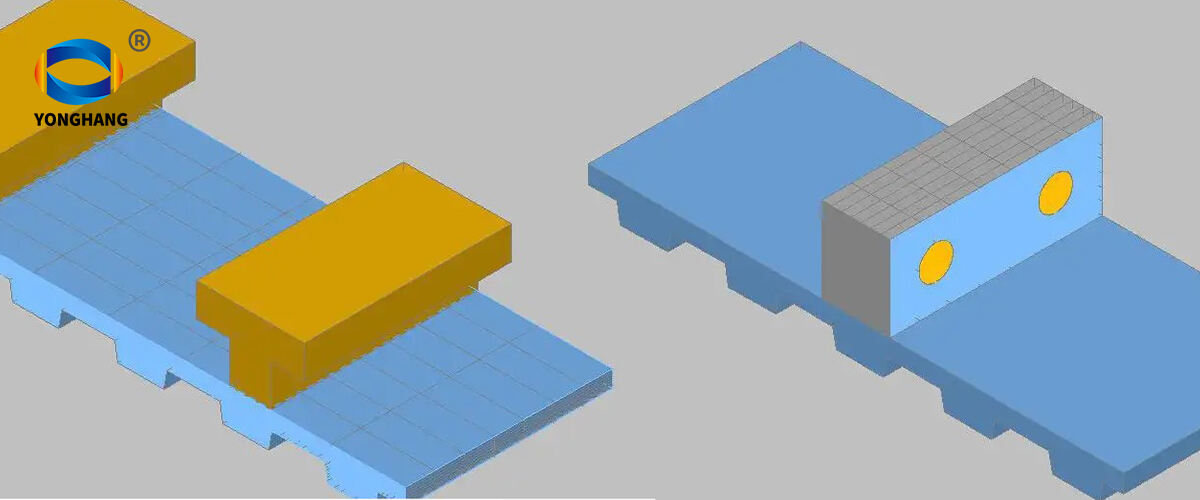

Design and Functionality of Cleated Timing Belts

Modern cleated timing belts employ three key engineering principles:

- Interlocking cleat patterns (T-shaped or L-shaped) that create pockets for product containment

- Reinforced tensile cords made from fiberglass or aramid fibers for dimensional stability under load

- Abrasion-resistant top covers that withstand up to 1,800 cycles/minute in demanding applications

Strategic cleat placement prevents harmonic vibrations that could compromise timing accuracy in servo-driven systems.

Key Advantages of Timing Belts with Cleats

Enhanced Grip and Load Stability

The cleats' geometric profile increases surface traction by up to 68% compared to flat belts, preventing product slippage during steep inclines or rapid starts/stops. Food processing plants leverage this feature to securely transport unstable containers without spills at 45° angles.

Precision and Control in Automated Conveying Systems

Cleat spacing aligns with robotic pick-and-place operations, enabling millimeter-accurate product positioning. Integrated synchronization ensures collision-free transfers between conveyor zones while maintaining <0.5mm alignment tolerance.

Reduced Slippage and Improved Synchronization

| Factor | Cleated Belt | Flat Belt |

|---|---|---|

| Start-up slippage | 0.3% | 4.1% |

| Speed variance | ±0.2 RPM | ±1.8 RPM |

| Maintenance cycles | 6,000 hrs | 2,500 hrs |

The interlocking cleat-pulley interface maintains angular synchronization within 0.05° even under 220kg loads.

Industrial Applications of Cleated Timing Belts

Cleated Timing Belts in Packaging Lines

Modern packaging lines require belts that maintain consistent product alignment at speeds exceeding 120 feet per minute:

- Prevent box slippage during abrupt conveyor direction changes

- Enable vertical product elevation in multi-level sorting systems

- Reduce packaging errors by 18% compared to flat belts

Food Processing and Beverage Production Uses

In USDA-grade facilities, cleated belts:

– Withstand daily high-pressure washdowns (up to 1,500 PSI)

– Maintain grip on wet containers without adhesives

– Operate contamination-free with FDA-compliant materials

Performance in Harsh Environments

| Environment Challenge | Cleated Belt Solution | Operational Benefit |

|---|---|---|

| Oil/Grease Exposure | Nitrile-coated cleats | 84% slip reduction |

| 140-300°F Temperatures | Thermoplastic urethane | 2x lifespan vs rubber |

| Metal Shard Abrasion | Aramid fiber backing | 90% tear resistance |

Installation Best Practices for Timing Belts with Cleats

Proper Tensioning and Alignment Techniques

Use a tension meter to achieve 3-5% elongation at installation—tight enough to prevent slippage but loose enough to avoid straining the reinforcement cords. Align pulleys within 0.5° angular deviation using laser alignment tools.

Matching Pulley Specifications to Cleated Belt Design

| Pulley Feature | Cleated Belt Requirement | Mismatch Consequence |

|---|---|---|

| Pitch Diameter | Matches cleat spacing ±0.2mm | Uneven load distribution |

| Groove Depth | 1.5x cleat height | Cleat deformation under load |

| Flange Angle | Parallel to cleat sidewalls | Premature edge wear |

Avoiding Common Installation Errors

Three critical mistakes account for 82% of installation-related failures:

- Over-tensioning: Increases bearing loads by 25-40%

- Mixed pulley materials: Creates uneven thermal expansion rates

- Ambient contamination: Dust accumulation decreases tracking precision

Maintenance and Replacement Guidelines

Signs of Wear and Fatigue

Visible indicators include surface cracks, frayed edges, or material hardening. Misalignment often causes uneven cleat wear or localized abrasion along edges.

Recommended Inspection Frequency

Follow manufacturer guidelines: high-speed packaging lines typically require monthly inspections, while moderate-use food processing systems need quarterly checks. Non-lubricated cleated belts in beverage plants lasted 18% longer when inspected bi-annually.

Replacement Protocols

Proactive replacement after 18-24 months of service prevents unplanned outages. Always replace belts and pulleys as matched sets—mismatched components account for 34% of premature wear.

FAQ

What materials are commonly used for cleated timing belts?

Common materials include rubber, polyurethane, and thermoplastic urethane, often reinforced with fiberglass or aramid fibers.

Can cleated timing belts be used in high-temperature environments?

Yes, cleated timing belts designed with thermoplastic urethane can withstand temperatures between 140-300°F, offering a longer lifespan compared to rubber.

How often should cleated timing belts be inspected?

Inspection frequency depends on usage. High-speed packaging lines typically require monthly inspections, while moderate-use systems need quarterly checks.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY