The Role of Round Belts in Modern Motion Control Systems

Understanding Motion Control and the Integration of Round Belt Systems

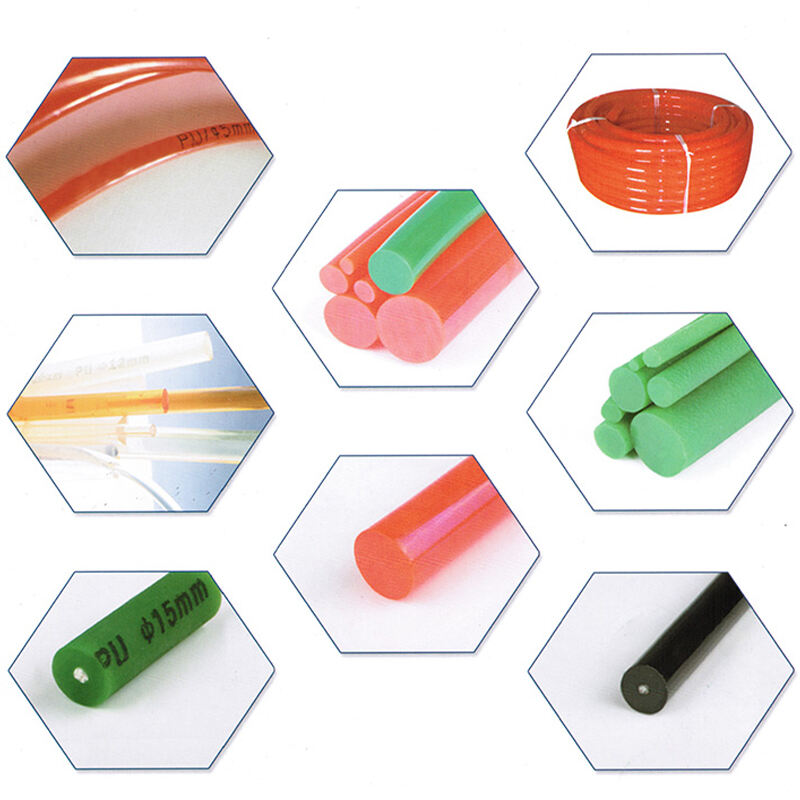

Today's motion control systems need all sorts of mechanical parts working together just right to handle things like speed control, positioning accuracy, and managing torque levels. Round belts work really well here because they have that round shape instead of flat or V-shaped profiles. This circular design lets them transfer power smoothly through those U or V shaped pulleys without much fuss. What sets them apart from regular flat or V-belts is how stretchy they can be. This elasticity means they don't need constant adjustment when installed, so alignment isn't such a big deal anymore and there's less maintenance involved over time. According to research published last year, switching to round belts cut down setup time by almost 20% in conveyor systems made up of multiple modules. That kind of efficiency explains why these belts show up everywhere from office printers to industrial packaging lines and even in delicate semiconductor manufacturing equipment where tight spaces and changing load conditions make traditional belts impractical.

Enhancing Responsiveness and Precision in Automation with Round Belts

Polyurethane and rubber round belts have a natural give that helps them handle small changes in load, which makes automated systems respond better overall. The way these materials absorb shocks cuts down on vibrations throughout the machinery. This matters a lot when doing delicate work such as positioning parts for robots or aligning optics where even tiny movements can cause problems. Looking at actual performance numbers from industrial settings, CNC feeders using round belts consistently hit position accuracy around ±0.1 mm. That's about 23 percent better than what most V-belt systems manage according to recent studies published by Industrial Automation Reports. Another big plus is their lightweight nature. We're talking roughly between 0.3 to 0.7 grams per cubic centimeter. This lighter weight means machines can speed up quicker during those fast pick-and-place operations that are so common in modern manufacturing environments.

Case Study: Round Belt Implementation in Semiconductor Handling Equipment

One major chip maker swapped out their old timing belts for 8mm polyurethane round belts on those wafer transfer robots they use all over the cleanrooms. What happened next was pretty impressive - almost all (like 92%) of those weekly tensioner tweaks just disappeared. And guess what? The noise level went down too, dropping from around 68 decibels down to a much quieter 54 dB. For over a year straight, these systems kept right on track with positioning accuracy staying within plus or minus 2 micrometers even after running nonstop for 20,000 hours. Pretty convincing stuff when it comes to showing why round belts work so well in cleanrooms where both pinpoint accuracy matters and keeping dust particles at bay is absolutely critical.

Power Transmission Efficiency: Advantages of Round Belts Over Flat and V-Belts

Evaluating Round Belt Performance Under Dynamic Loads

Round belts excel in dynamic load scenarios due to their elastic properties, which enable adaptive load distribution across pulleys. Unlike rigid belt profiles, the circular cross-section minimizes localized stress concentrations—a critical advantage in applications like packaging machinery with frequent speed variations.

Energy Transfer Efficiency Compared to Flat and V-Belts

The continuous surface contact of round belts reduces slippage by 23% compared to traditional flat and V-belts in low-to-medium torque applications. This efficiency stems from two key factors:

- Elastic Deformation: Compressive flexibility allows better conformity to pulley grooves

- Uniform Tension Distribution: Eliminates edge wear common in V-belts

| Metric | Round Belts | Flat Belts | V-Belts |

|---|---|---|---|

| Speed Range | 0.5–15 m/s | 1–25 m/s | 2–30 m/s |

| Optimal Torque | <150 Nm | <300 Nm | <500 Nm |

Limitations in High-Torque Applications

While round belts outperform competitors in efficiency at moderate loads, their elasticity becomes a liability in high-torque scenarios (>200 Nm). The 6:1 minimum pulley diameter rule (relative to belt thickness) restricts compact designs, making them less viable than reinforced V-belts in heavy machinery.

Flexibility and Compact Design: Round Belts in Conveyor and Modular Systems

Adaptability in Conveyor Systems Using Round Belt Technology

Round belts work really well in conveyor setups that need constant rearranging because they stretch and bend in all directions. Flat belts require everything to line up just right, but round belts can handle when pulleys aren't perfectly aligned or when loads shift around during operation. They still transfer power consistently even under these conditions. Food processing plants and logistics centers find these belts particularly useful since their conveyor arrangements tend to get changed up throughout different seasons as products come and go. Many manufacturers have switched to round belts simply because they save time on setup changes and reduce downtime when adjusting production lines for new items.

Design Freedom Through Compact Routing and 3D Path Configurations

Round belts have a circular cross section which makes them really good at moving through three dimensional spaces around obstacles where flat belts just won't work. Take pharmaceutical packaging lines for instance these systems need to weave past all sorts of equipment like sensors and robotic arms while still keeping production going strong. Some engineers working in automated warehouses have actually seen space savings of around 40 percent when they switch to round belts for those twisty conveyor routes. Traditional belt systems would need several motors to do what one round belt can handle, making them much less efficient overall.

Trend: Rising Adoption in Modular Conveyor Designs for E-Commerce Fulfillment

Big online retailers are starting to roll out round belt systems across their modular conveyor networks, especially when inventory needs spike during holiday rushes or sales events. These belt systems can manage all sorts of odd-shaped stuff - think smartphones, clothing bundles, even bulky winter gear - without getting backed up, which matters a lot since customer orders keep changing at around 18% each year. What makes these round belts stand out is how they automatically stay tight, so workers don't have to constantly tweak them like they do with those old chain-based systems. The whole setup just adapts faster to whatever comes through next on the assembly line.

Strategy: Optimizing Pulley Groove Geometry to Extend Belt Life

Proactive groove design reduces round belt wear by 30% in high-speed applications:

- Groove depth: 1.2–1.5x belt diameter prevents slippage under lateral loads

- Groove angle: 30°–40° balances grip and friction heat generation

- Material pairing: Urethane pulleys minimize abrasion against rubber belts

By matching groove profiles to specific operating temperatures and belt materials, facilities achieve maintenance intervals exceeding 12,000 hours in 24/7 sorting operations.

Material Handling Performance: Round Belts in Sensitive and Demanding Environments

Round Belts in Pharmaceutical Packaging and Food Processing Lines

Round belts really shine in places where keeping things clean matters most. Take those blister packaging machines used in pharmacies for instance their smooth surfaces just don't create particles like other belt types might, which meets those strict ISO 14644-1 requirements for cleanrooms. For food processing too, these belts hold up against all sorts of oils and cleaning agents without breaking down, so they work great on conveyor systems in meat slicing operations and bakery cooling lines where FDA compliance is non-negotiable. What makes them stand out from regular chains? Well, the way they're designed as one continuous loop means there are no little gaps or corners where bacteria can hide and grow, something that gives manufacturers peace of mind when hygiene is absolutely critical.

Performance With Sensitive Products and Hygienic Requirements

Polyurethane round belts have this great elastic memory feature that stops surfaces from getting scratched or damaged when moving around delicate stuff like vaccine vials or freshly picked fruits. The USDA approved versions can handle those intense pressure washes we do every day at facilities (they take up to about 1500 pounds per square inch!) without breaking down like regular rubber belts tend to do since they soak up all that water. When it comes to working with candies and sweets, these belts come with special food safe silicone coatings. These coatings keep the surface super smooth at under half a micrometer roughness which helps prevent sticky products from sticking during packaging. Tests show this works roughly 47 percent better than those old fashioned textured belts when wrapping things like caramel snacks.

Strategy: Selecting Optimal Belt Materials (PU vs. Rubber) for Specific Environments

| Parameter | Polyurethane (PU) | Rubber |

|---|---|---|

| Temperature Range | -40°C to 90°C | -20°C to 110°C |

| Chemical Exposure | Resists oils, weak acids | Degrades with solvents |

| Tensile Strength | 45–55 MPa | 20–30 MPa |

| Hygiene Compliance | NSF/3A certified options | Limited certifications |

Polyurethane (PU) has become the go to material for cold chain logistics applications like those -18 degree Celsius freezer conveyor systems and chemical packaging lines because it stands up well against hydrolysis. When it comes to oven transfer systems in baking tunnels that operate at around 100 degrees Celsius or below, rubber is still what most people reach for. The reason? Even though rubber isn't as strong mechanically, it handles thermal expansion much better in these conditions. Now there's something new on the market though recent developments in thermoplastic elastomer (TPE) belts are starting to fill the space between these options. These newer TPE materials can withstand temperatures up to about 80 degrees while maintaining that easy to clean surface characteristic of PU, making them an interesting alternative for many manufacturers looking for middle ground solutions.

Elasticity, Self-Tensioning, and Low-Noise Operation in Precision Applications

How Elasticity and Self-Tensioning Reduce Maintenance in Round Belt Systems

Round belts leverage inherent elasticity to maintain optimal tension without manual adjustments, reducing downtime in automated systems. This self-tensioning capability compensates for thermal expansion and wear, decreasing maintenance intervals by up to 30% in continuous operations like packaging lines.

Mechanical Behavior Under Thermal Expansion and Load Fluctuations

Tests show round belts retain 92% of initial tension stability across -20°C to 80°C ranges, outperforming traditional V-belts in environments with rapid temperature shifts. Their uniform stress distribution prevents localized wear during load spikes, a critical advantage for semiconductor manufacturing equipment.

Case Study: Long-Term Tension Stability in 24/7 Food Processing Conveyors

A leading frozen food producer achieved 18 months of uninterrupted operation using polyurethane round belts, compared to 8-month replacement cycles with previous flat belt systems. The belts' elasticity accommodated daily thermal cycling from -30°C blast freezers to 25°C packaging areas.

Low-Noise Advantages in Medical, Lab, and Office Automation Equipment

Round belts operate at <55 dB in MRI conveyor systems and document sorters, meeting hospital noise regulations (ISO 11690-1) while maintaining positional accuracy to ±0.1 mm. This silent operation enables integration in noise-sensitive environments like diagnostic labs.

Trade-Off: High Elasticity Improves Shock Absorption but May Affect Positional Accuracy

While round belts absorb 40% more vibration than synchronous belts (ASTM D430-B testing), their stretch can introduce ±0.25° rotational lag in high-precision robotics. Engineers compensate through overspeed protocols in pick-and-place applications requiring <5㎛ repeatability.

FAQ

What are the main advantages of using round belts over flat and V-belts?

Round belts offer improved elasticity, reduced maintenance due to less frequent tension adjustments, and better shock absorption. They are especially suitable for systems that require flexibility in design and freedom of movement in three-dimensional space.

In what applications are round belts most effective?

Round belts are most effective in clean environments such as semiconductor manufacturing and pharmaceuticals, as well as in automation tasks that require precision and reduction in noise. They are also beneficial in conveyor systems that require frequent reconfiguration and compact design.

How do round belts handle high-torque applications?

While round belts are efficient in moderate load conditions, they are less suitable for high-torque applications due to their elasticity. For heavy machinery requiring high torque, reinforced V-belts are generally more practical.

Can round belts be used in food processing environments?

Yes, round belts are ideal for food processing environments due to their smooth, cleanable surfaces that do not harbor bacteria. They are also resistant to oils and cleaning agents, making them compliant with FDA standards.

What materials are round belts made from, and how do these materials affect performance?

Round belts are commonly made from polyurethane or rubber. Polyurethane belts are suitable for environments with low temperatures and potential chemical exposure, while rubber belts are better for high-temperature conditions. Each material offers unique benefits depending on the application requirements.

Table of Contents

- The Role of Round Belts in Modern Motion Control Systems

- Power Transmission Efficiency: Advantages of Round Belts Over Flat and V-Belts

- Evaluating Round Belt Performance Under Dynamic Loads

- Energy Transfer Efficiency Compared to Flat and V-Belts

- Limitations in High-Torque Applications

- Flexibility and Compact Design: Round Belts in Conveyor and Modular Systems

- Material Handling Performance: Round Belts in Sensitive and Demanding Environments

-

Elasticity, Self-Tensioning, and Low-Noise Operation in Precision Applications

- How Elasticity and Self-Tensioning Reduce Maintenance in Round Belt Systems

- Mechanical Behavior Under Thermal Expansion and Load Fluctuations

- Case Study: Long-Term Tension Stability in 24/7 Food Processing Conveyors

- Low-Noise Advantages in Medical, Lab, and Office Automation Equipment

- Trade-Off: High Elasticity Improves Shock Absorption but May Affect Positional Accuracy

-

FAQ

- What are the main advantages of using round belts over flat and V-belts?

- In what applications are round belts most effective?

- How do round belts handle high-torque applications?

- Can round belts be used in food processing environments?

- What materials are round belts made from, and how do these materials affect performance?

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY