ATM belts serve as the backbone of cash handling systems, directly influencing transaction speed, accuracy, and reliability. Their textured surfaces grip bills without slippage while navigating rollers and gears precisely—misalignment or wear can trigger sensor errors leading to transaction failures.

Modern ATM systems increasingly rely on robust belt designs to meet 24/7 availability expectations. Financial institutions that implement proactive replacement cycles reduce unplanned outages by 62% compared to reactive repairs, preserving operational continuity.

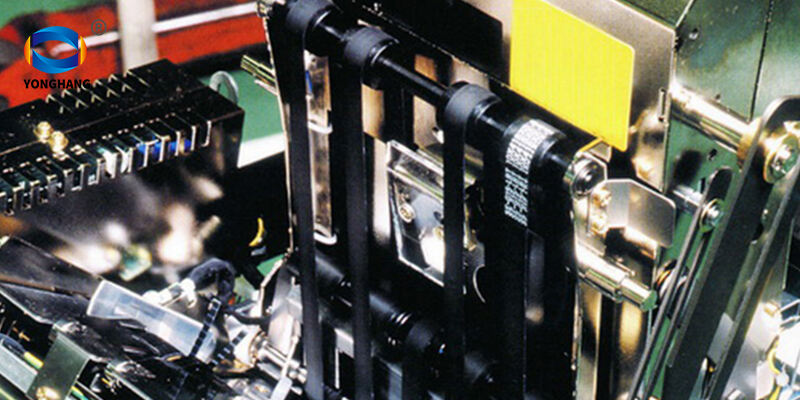

How ATM Belts Support Cash Handling and Dispensing Mechanisms

Precision engineering ensures bills move seamlessly from storage cassettes to dispensing mechanisms. Field tests show even a 0.1mm deviation in belt alignment increases dispensing errors by 34%, underscoring the need for micron-level accuracy.

Key performance factors include:

- Material composition: Layered polymers with nylon-reinforced cores withstand 100,000+ dispensing cycles

- Tension consistency: Maintaining 18-22 N/mm² prevents misfeeds

- Surface integrity: Micro-cracks in high-friction zones accelerate wear

Impact of Belt Performance on ATM Uptime and Service Reliability

Worn belts account for 41% of mechanical failures in ATMs, particularly in urban areas processing 3,000+ transactions monthly. The consequences cascade:

- Slowed transaction speeds

- Increased jam rates (60% higher in non-compliant systems)

- Complete system halts

Technicians using laser tension meters and digital calipers during quarterly maintenance reduce failure rates by 85% when adhering to ISO 13050:2015 tolerances.

Design and Materials: Engineering Durable ATM Belts

Core Materials for Durability and Flexibility

Modern belt designs combine:

- Polyurethane or rubber layers (last 2-3 years vs. traditional rubber)

- Nylon-reinforced cores

- Heat-resistant insulation

Hybrid materials demonstrate 40% better abrasion resistance and accommodate ±3% elongation without integrity loss—critical for aging mechanisms.

Precision in Thickness, Tension, and Alignment

Industry standards mandate:

| Parameter | Tolerance |

|---|---|

| Thickness | ±0.15mm |

| Tension | 18-22 N/mm² |

| Alignment | <0.5° deviation |

Machines meeting these specs experience 60% fewer jams. Edge wear exceeding 2% of initial belt length precedes 34% of unplanned outages.

Common Failures and Their Impact on ATM Performance

Slippage and Misalignment

34% of ATM errors originate from belt slippage, often in machines processing 2,000+ weekly transactions. Just 1mm misalignment causes:

- Skewed bill feeds

- False jam alerts

- Incomplete transactions

Monthly alignment checks reduce these failures by 72%.

Wear and Tear in High-Traffic ATMs

Urban ATMs endure:

- 15kg lateral force per withdrawal

- 40+ friction cycles per transaction

- 18hrs/day operation

Belt lifespan decreases by 40% in units processing 500+ daily withdrawals, necessitating 6-month (vs. 12-month) replacement cycles.

Contamination by Dust and Debris

Each transaction introduces 0.3mg particulate matter—18% of failures stem from:

- Salt corrosion (coastal areas)

- Concrete dust (construction zones)

- Mold spores (high humidity)

Quarterly deep cleaning with HEPA filters reduces particulate-related repairs by 61%.

Preventive Maintenance for Extended ATM Belt Lifespan

Proactive maintenance reduces cash-handling failures by 38%. Key strategies:

Scheduled Inspection Protocols

Quarterly checks should verify:

- Alignment (<0.5mm deviation)

- Tension (4.2-4.6 N/mm²)

- Surface integrity (micro-cracks)

Banks performing monthly visual audits report 52% fewer emergency replacements.

Cleaning and Lubrication Best Practices

In coastal regions, bi-monthly cleaning:

- Removes salt deposits

- Neutralizes polymer note residues

- Restores friction coefficients

Food-grade silicone lubricant on roller bearings every 6,000 cycles reduces flexural stress by 19%.

Innovations in ATM Belt Technology

Smart Belts with Embedded Sensors

IoT-enabled belts monitor:

- Real-time tension

- Wear patterns

- Alignment accuracy

Early adopters achieve 72% fewer service calls by predicting failures before jams occur.

Advanced Materials

Next-gen belts feature:

- Carbon-fiber layers (3x lifespan)

- Hydrophobic surfaces (98% dust repellent)

- Self-lubricating fibers (90% less friction wear)

These handle 50,000+ cycles without degradation, even in extreme climates.

AI-Driven Diagnostics

Machine learning analyzes 23 operational variables to:

- Schedule replacements during maintenance windows

- Predict failures 14 days in advance (89% accuracy)

- Reduce maintenance outages by 30%

This integration revolutionizes cash availability guarantees for next-generation ATMs.

Frequently Asked Questions

What are the key factors in maintaining ATM belts?

Key factors include maintaining proper alignment, tension consistency, and surface integrity to prevent errors and prolong belt life.

How frequently should ATM belts be replaced?

This depends on usage; high-traffic ATMs may need replacements every six months, while others might require annual replacement.

What are the benefits of proactive maintenance for ATM belts?

Proactive maintenance reduces unexpected outages and extends belt lifespan, leading to fewer emergency replacements and better machine performance.

What innovations are emerging in ATM belt technology?

Innovations include smart belts with sensors, advanced materials like carbon-fiber, and AI-driven diagnostics for predictive maintenance.

Table of Contents

- How ATM Belts Support Cash Handling and Dispensing Mechanisms

- Impact of Belt Performance on ATM Uptime and Service Reliability

- Design and Materials: Engineering Durable ATM Belts

- Common Failures and Their Impact on ATM Performance

- Slippage and Misalignment

- Wear and Tear in High-Traffic ATMs

- Contamination by Dust and Debris

- Preventive Maintenance for Extended ATM Belt Lifespan

- Scheduled Inspection Protocols

- Cleaning and Lubrication Best Practices

- Innovations in ATM Belt Technology

- Smart Belts with Embedded Sensors

- Advanced Materials

- AI-Driven Diagnostics

- Frequently Asked Questions

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY