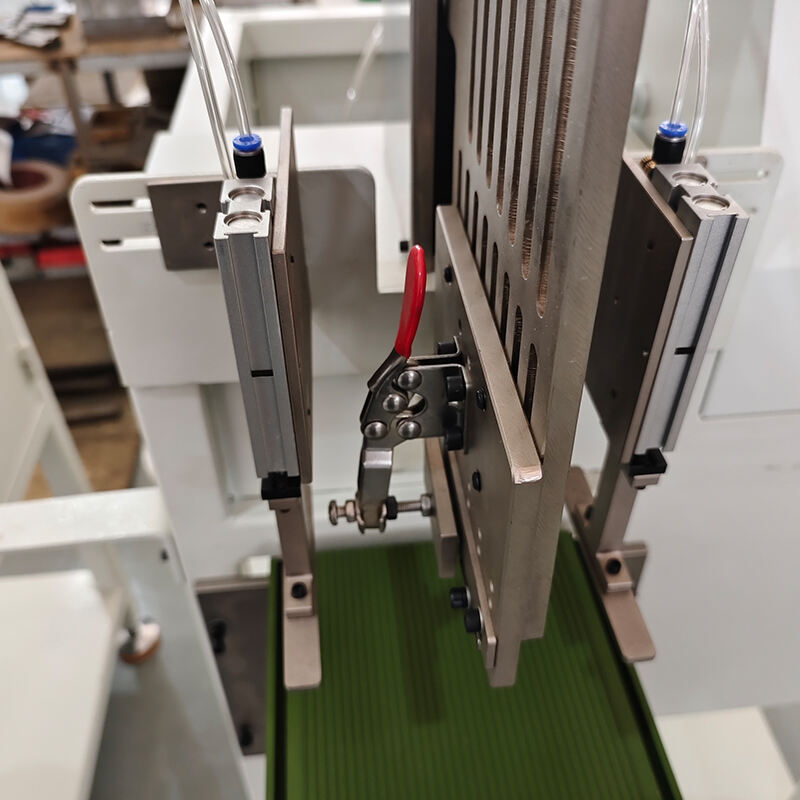

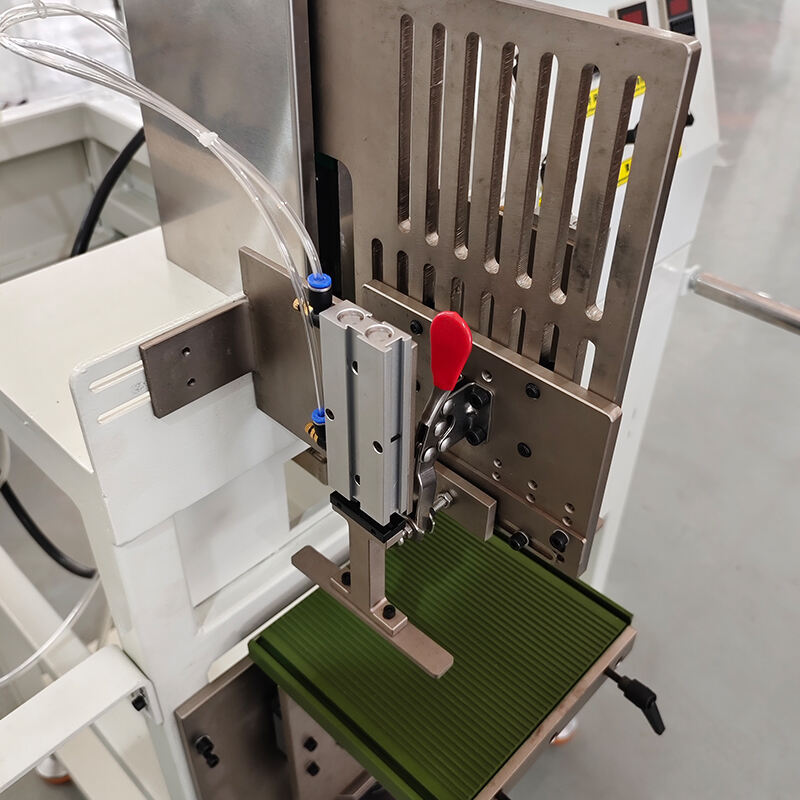

Μηχάνημα ιμάντα χρονικής ζώνης με πλάκα διαχωρισμού

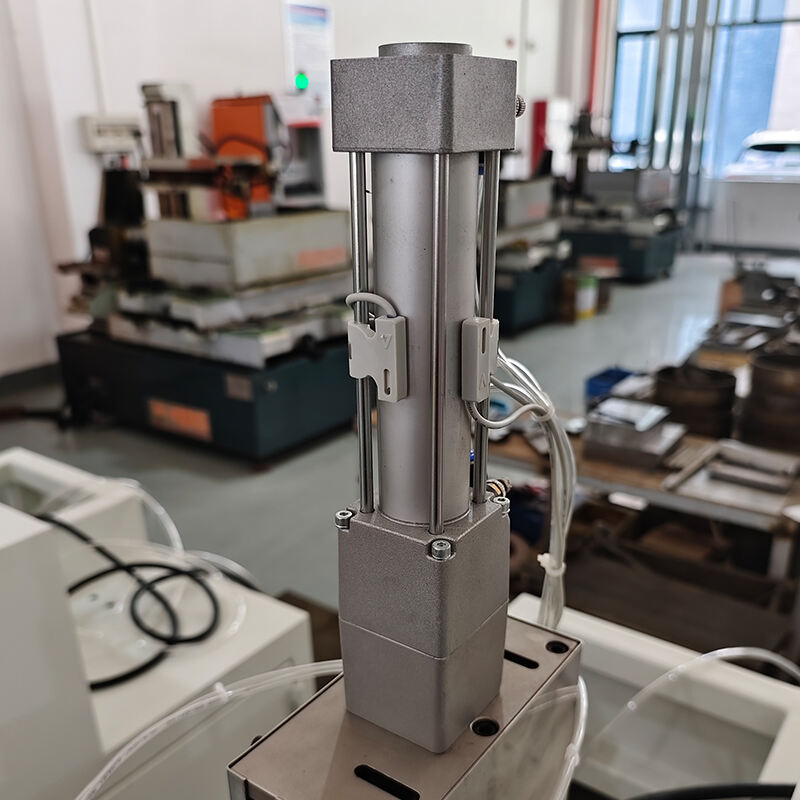

Το μηχάνημα τσιμέντου χρονισμού YONGHANGBELT συν αεραγωγό είναι εξειδικευμένος εξοπλισμός που έχει σχεδιαστεί για την ακριβή, αυτόματη συναρμολόγηση στοπ και (κλειδώματος θέσης) στην αντίστροφη πλευρά οδοντωτών ιμάντων. Μέσω υψηλής ακρίβειας ευθυγράμμισης, στερεώνει με ασφάλεια μεταλλικά ή πλαστικά στοπ στο σώμα του ιμάντα μέσω κόλλησης ή καρφώματος. Αυτή η διαδικασία αποτελεί σημαντικό στάδιο παραγωγής για την επίτευξη λειτουργικότητας γραμμικής μετάδοσης και ακριβούς ευθυγράμμισης στους ιμάντες.

- Εισαγωγή

Εισαγωγή

Χαρακτηριστικά:

- Ακριβής τοποθέτηση: Η ακρίβεια διαστήματος συναρμολόγησης του στοπ φτάνει το ±0,1 mm, εξασφαλίζοντας ακριβή τοποθέτηση μετάδοσης.

- Υψηλή παραγωγικότητα: Ο αυτοματοποιημένος κύκλος επιτρέπει ταχύτητες συναρμολόγησης 800–1500 μονάδων την ώρα, αυξάνοντας σημαντικά την παραγωγικότητα.

- Ευρεία προσαρμοστικότητα: Συνήθως χειρίζεται ιμάντες συγχρονισμού πλάτους 10–200 mm και ύψους στοπ 5–50 mm.

- Ισχυρή κόλληση: Ενσωματώνει μηχανισμούς πίεσης και συστήματα άμεσης σκλήρυνσης (π.χ. σκλήρυνση UV κόλλης ή κόλληση με τήξη) για εγγύηση της αντοχής της κόλλησης.

- Έξυπνη ευελιξία: Με ελεγκτή PLC και λειτουργία μέσω οθόνης αφής, μπορεί να αποθηκεύει πολλές συνταγές για γρήγορη εναλλαγή μεταξύ διαφορετικών διαστημάτων στοπ και μοντέλων.

Αυτός ο εξοπλισμός αποτελεί απαραίτητη υψηλού επιπέδου μηχανή για την παραγωγή ακριβείας ιμάντων μετάδοσης και τοποθέτησης (π.χ. ιμάντες βηματισμού ανελκυστήρα, ιμάντες μετάδοσης για αυτοματοποιημένο εξοπλισμό).

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY