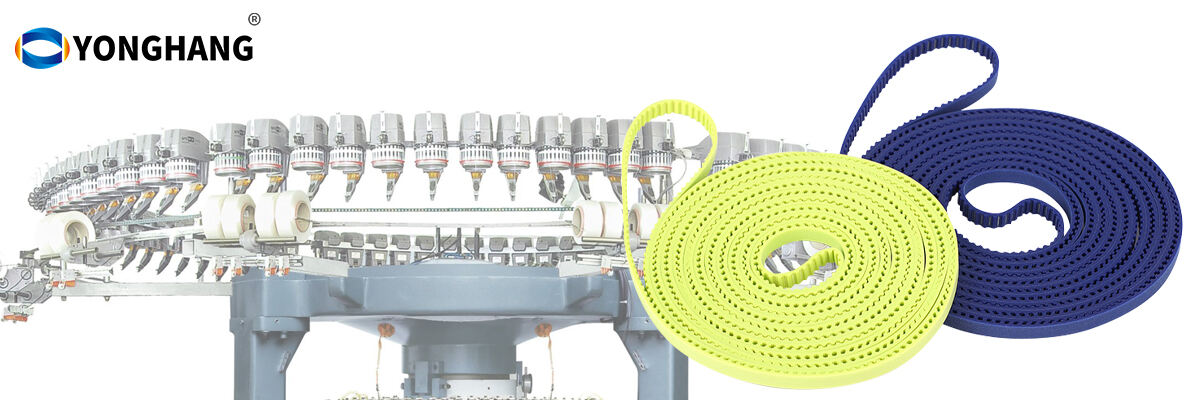

สายพานเครื่องถัก - หัวใจหลักของการส่งกำลังที่แม่นยำสำหรับเครื่องถักผ้าแบบกลม

ในอุตสาหกรรมสิ่งทอ การทำงานอย่างมีประสิทธิภาพของเครื่องกลมขนาดใหญ่ มีผลโดยตรงต่อคุณภาพของผ้าและประสิทธิภาพการผลิต สายพานจังหวะ TT5 แบบโพลียูรีเทน ซึ่งเป็นชิ้นส่วนสำคัญในการส่งกำลัง ทำหน้าที่สำคัญในการรับประกันการทำงานแบบซิงโครไนซ์ของล้อส่งกำลังหลายสิบตัว หากสายพานเกิดสึกหรอ ยืดออก หรือขาด จะอาจก่อให้เกิดข้อบกพร่องบนผ้า หรือทำให้ผ้าทั้งล็อตถูกทิ้งได้ ดังนั้น การเลือกใช้สายพานเครื่องถักคุณภาพสูงจึงมีความสำคัญอย่างมาก สายพานเครื่องถัก จึงมีความสำคัญ

1. โครงสร้างและประโยชน์ของสายพานเครื่องถัก

สายพานเครื่องถักนิตติ้งประกอบด้วยสองส่วนหลักดังนี้:

ชั้นนอกโพลียูรีเทน: มีคุณสมบัติกันการสึกหรอได้ดี และลดเสียงรบกวน เหมาะสำหรับใช้งานเป็นเวลานานในโรงงานสิ่งทอ และลดมลภาวะทางเสียงของอุปกรณ์

แกนเหล็กกล้าความแข็งแรงสูง: มีความทนทานต่อแรงดึงได้อย่างยอดเยี่ยม ไม่มีการบิดงอหรือขาดแม้จะใช้งานภายใต้ภาระหนักเป็นเวลานาน ช่วยให้การส่งกำลังมีความแม่นยำคงที่

2. ทำไมเครื่องถักผ้าขนาดใหญ่แบบกลมจึงต้องพึ่งพา สายพานเครื่องถัก ?

การส่งกำลังแบบซิงโครไนซ์อย่างแม่นยำ: โครงสร้างฟันเฟือง TT5 (ระยะห่างฟัน 5 มม.) ทำให้เพลาขับทุกตัวหมุนด้วยความเร็วที่เท่ากัน ป้องกันข้อบกพร่องเช่น รอยขวางหรือจุดบกพร่องบนผ้า

ทนทานต่อการสึกกร่อนและอายุการใช้งานยาวนานกว่า: วัสดุโพลียูรีเทนมีคุณสมบัติต้านทานการเสื่อมสภาพได้ดี สามารถยืดอายุการใช้งานให้นานขึ้นกว่า 30% เมื่อเทียบกับสายพานยางธรรมดา

ปรับตัวให้เข้ากับสภาพแวดล้อมที่รุนแรง: กันน้ำมัน กันฝุ่น อุณหภูมิ (-30℃~80℃ และความชื้นสูงมาก รวมถึงมีเส้นใยผ้าลอยอยู่จำนวนมากในโรงงานผลิตสิ่งทอ

3. การพิจารณาว่าสายพานเครื่องถักต้องเปลี่ยนหรือไม่?

สายพานหย่อน: สายพานไม่ได้รับการดึงตึงเพียงพอ ทำให้ทำงานไม่ราบรื่น ส่งผลให้เกิดการถ่ายทอดกำลังไม่เหมาะสม และนำไปสู่ข้อบกพร่องบนพื้นผ้าซึ่งเกิดขึ้นเป็นประจำ

ฟันสึก: ฟันแบนหรือแตก หมายความว่า การที่ตัวฟันซี่แรกเชื่อมต่อกันไม่เพียงพอ และฟันซี่ถัดไปเชื่อมต่อกันไม่เพียงพอ หมายความว่า การสบฟันไม่ถูกต้อง

แกนเหล็กโผล่: แกนสายพานหักหรือโผล่ออกมา หมายความว่าสายพานสามารถขาดได้ตลอดเวลา

แม้ว่าสายพานเครื่องถักจะมีขนาดเล็ก แต่กลับเป็นส่วนสำคัญที่ทำให้เครื่องกลมใหญ่ทำงานได้อย่างเสถียร การเลือกใช้สายพานที่มีความแม่นยำสูงและทนทานสูง จะช่วยรับประกันประสิทธิภาพในการผลิตและความมีคุณภาพของผ้าอย่างมั่นคง เรามีประสบการณ์ด้านระบบส่งกำลังในอุตสาหกรรมสิ่งทอมาแล้ว 12 ปี และจัดจำหน่ายสายพานแบบ TT5 ที่มีคุณภาพหลากหลายขนาด ยินดีต้อนรับปรึกษาและให้เราช่วยคุณหาทางแก้ไขที่ดีที่สุดตามความต้องการของคุณ

>>คลิก "YONGHANG® สายพานเวลา " เพื่อข้อมูลเพิ่มเติมเกี่ยวกับผลิตภัณฑ์ของเรา!

YONGHANG® Transmission Belt ด้วยประสบการณ์อันยาวนานมากกว่า 20 ปีในวงการ บริษัทได้รวมเอาการวิจัยและพัฒนา การผลิตและการปรับแต่ง ODM&OEM Service, ใบรับรอง CE RoHs FDA ISO9001, ศูนย์วิจัยและพัฒนา พื้นที่โรงงานมากกว่า 10,000m²+ แม่พิมพ์ เครื่องจักรความแม่นยำมากกว่า 50+ เซ็ต เครื่องมือแม่พิมพ์มากกว่า 8000+ เซ็ต ทีมวิจัยและพัฒนาทางเทคนิค มุ่งเน้นการผลิตอย่างแม่นยำ ให้บริการปรับแต่งผลิตภัณฑ์ระบบส่งกำลังคุณภาพสูงแบบครบวงจร! ยินดีต้อนรับสู่ www.yonghangbelt.com เพื่อข้อมูลเพิ่มเติม! บทความลิขสิทธิ์: YONGHANG® Transmission Belt กรุณาระบุแหล่งข้อมูล ขอบคุณสําหรับความร่วมมือ

กรุณาติดต่อเราตรงเพื่อขอข้อมูลเพิ่มเติมเกี่ยวกับความต้องการเฉพาะของคุณ

URL:http://www.yonghangbelt.com

Whatapp&wechat:+ 0086 13725100582

Email :[email protected]

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY