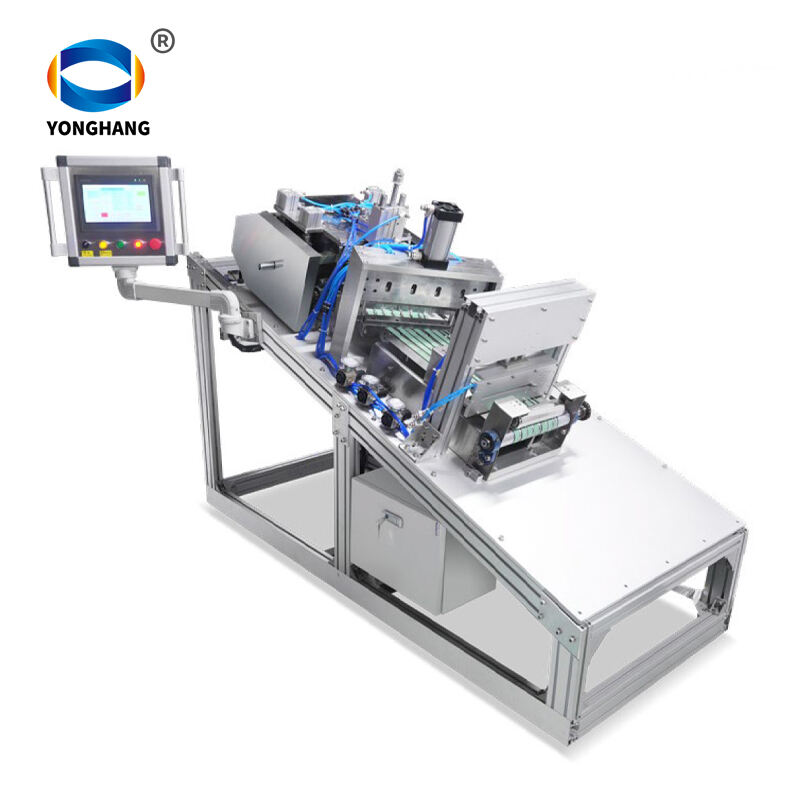

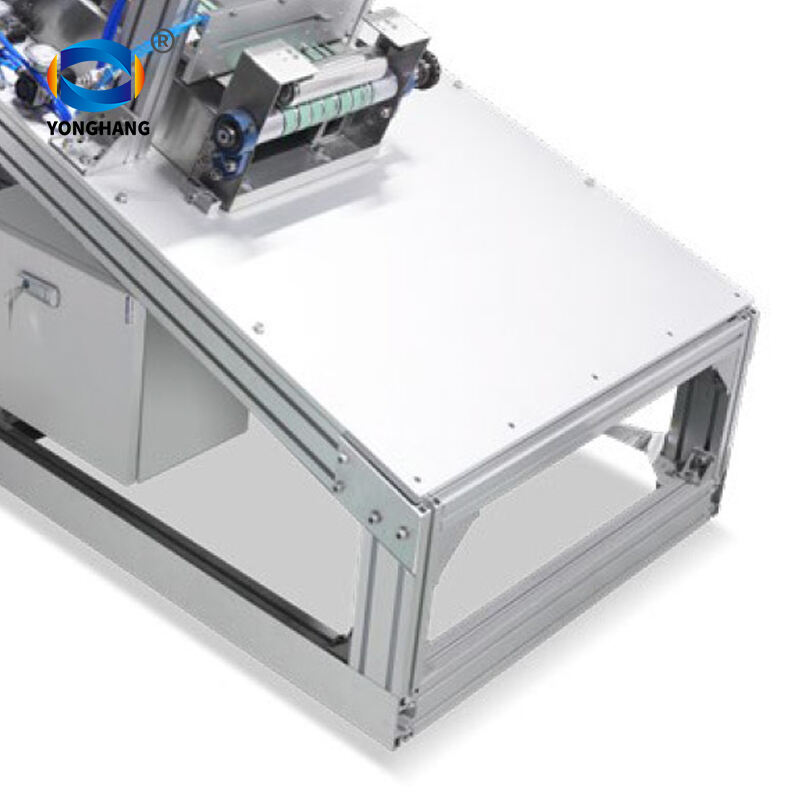

ကွန်ဗာတာခါးပတ်တိုင်းတာစက်

YONGHANG ကွန်ဗေယာခါးပတ်တိုင်းတာစက်သည် စက်ဝိုင်းပုံကွန်ဗေယာခါးပတ်များအတွက် အထူးဒီဇိုင်းထုတ်ထားသော မြင့်မားသောတိကျမှု၊ အလိုအလျောက်အရှည်စစ်ဆေးရေးကိရိယာတစ်ခုဖြစ်သည်။ တိကျသော stepper မော်တာမောင်းနှင်မှုနှင့် ဉာဏ်ရည်ထက်မြက်သောထိန်းချုပ်မှုနည်းပညာကို အသုံးပြု၍ ရိုးရာတိပ်တိုင်းတာနည်းလမ်းများနှင့်ဆက်စပ်သော စက်မှုလုပ်ငန်းစိန်ခေါ်မှုများ - ဆိုလိုသည်မှာ ထိရောက်မှုနည်းပါးခြင်း၊ တိုင်းတာမှုအမှားများသိသာထင်ရှားခြင်းနှင့် ထပ်ခါတလဲလဲလုပ်ဆောင်နိုင်မှုညံ့ဖျင်းခြင်းတို့ကို ဖြေရှင်းပေးသည်။ ဤကိရိယာသည် ပြားချပ်ချပ်ခါးပတ်များ၊ V-ခါးပတ်များနှင့် synchronous ခါးပတ်များအပါအဝင် စက်ဝိုင်းပုံကွန်ဗေယာခါးပတ်အမျိုးမျိုး၏ အတွင်းပိုင်းပတ်လည်၊ အပြင်ဘက်ပတ်လည်နှင့် ထိရောက်သောအရှည်ကို လျင်မြန်စွာနှင့် တိကျစွာတိုင်းတာသည်။ ၎င်းသည် ကွန်ဗေယာခါးပတ်ထုတ်လုပ်မှု၊ ဝယ်ယူမှုလက်ခံခြင်း၊ အစားထိုးတပ်ဆင်ခြင်းနှင့် စာရင်းစီမံခန့်ခွဲမှုအတွက် အဓိကမက်ထရိုလိုဂျီကိရိယာတစ်ခုအဖြစ် ဆောင်ရွက်သည်။

- မိတ်ဆက်ခြင်း

မိတ်ဆက်ခြင်း

အထူးသဖြင့်:

မီတာရိုလော်ဂျီအဆင့် တိကျမှု

±0.1% တိကျမှုစံကို အသုံးပြုခြင်းဖြင့် တိုင်းတာမှုမှားယွင်းမှုကြောင့် ဖြစ်ပေါ်လာသော ပစ္စည်းနှင့် အချိန်ဆုံးရှုံးမှုများကို အခြေခံအားဖြင့် ဖယ်ရှားပေးပါသည်။ ဥပမာ - ကွန်ဗီဟိုင်ယာဘဲလ်များ 'အလွန်ရှည်ပြီး ဖြတ်တောက်ရသည်' သို့မဟုတ် 'အလွန်တိုပြီး စွန့်ပစ်ရသည်' စသည့် အခြေအနေများ။

အလိုအလျောက် ဉာဏ်ရည်ထက်မီသော တိုင်းတာမှု

ဘဲလ်ကို ကလမ်ပ်ဖြင့် ကိုင်ထားခြင်း၊ အလိုအလျောက် ဆွဲယူခြင်းမှစ၍ အလျားတွက်ချက်ခြင်းနှင့် ပြသခြင်းအထိ လုံးဝအလိုအလျောက် လုပ်ငန်းစဉ်ဖြစ်ပါသည်။ အဆုံးအလျားကို LCD မျက်နှာပြင်တွင် တိုက်ရိုက်ပြသပေးခြင်းဖြင့် လက်တွက်ဖတ်ရှုမှုနှင့် တွက်ချက်မှုအမှားများကို ဖယ်ရှားပေးပါသည်။

ထူးခြားသော ထပ်တလဲလဲတိုင်းတာမှု တည်ငြိမ်မှု

'ယုံကြည်စိတ်ချရသော တိုင်းတာမှုရလဒ်များ' နှင့် 'အဆင်ပြေသော တိုင်းတာမှုလုပ်ငန်းစဉ်' တို့သည် အတူတူအရေးကြီးပါသည်။ ±0.1% အထိ ထပ်တလဲလဲတိုင်းတာမှုတိကျမှုသည် တစ်ဦးတည်းက တစ်ချိန်ကို အကြိမ်ကြိမ်တိုင်းတာသည်ဖြစ်စေ၊ မတူညီသော ဝန်ထမ်းများက တိုင်းတာသည်ဖြစ်စေ တည်ငြိမ်ပြီး ယုံကြည်စိတ်ချရသော ရလဒ်များကို အာမခံပေးပါသည်။

ပတ်ဝန်းကျင် အကျိုးသက်ရောက်မှု အား မြင်းမြှင့်

-20°C မှ 50°C အထိ ကျယ်ပြန့်သော အပူချိန်အကွာအဝေးတွင် အလုပ်လုပ်ပြီး ရာသီဥတု သို့မဟုတ် စက်ရုံအတွင်း အပူချိန်ပြောင်းလဲမှုများကို လုံးဝမထိခိုက်ဘဲ အများဆုံး စက်မှုလုပ်ငန်းနယ်ပယ်များတွင် ယုံကြည်စိတ်ချစွာ အလုပ်လုပ်နိုင်ပါသည်။

ကျယ်ပြန့်သော အသုံးချမှု ကိုက်ညီမှု

ရာဘာ၊ PVC၊ PU၊ ကန်ထေးစသည့်ပစ္စည်းများဖြင့်ပြုလုပ်ထားသော ပိုက်ဆက်ပြား၊ ဘေးဘီးပါ ပိုက်ဆက်ပြားနှင့် အခြားသော ပိုက်ဆက်ပြားများအတွက် သင့်တော်ပြီး အသုံးဝင်မှုမြင့်မားသည်။

ထုတ်ကုန်အချက်အလက်များ:

| လုပ်ငန်းရှိအားကြီး | 220V |

| အလုပ်လုပ်လေဖိအား | 4kg |

| လျှပ်စစ်အား | 650W |

| တိုင်းတာမှုအကွာအဝေး | 200mm အသုံးဝင်သော အကျယ်: 200mm |

| အလျားတိုင်းတာမှု တိကျမှု | 5 မီတာအတွင်း ±0.1% (±1mm); 5 မီတာကျော်လျှင် ±0.1% |

| ပြန်လည်လုပ်ဆောင်မှုတူညီချက် | ±0.1% |

| ဝိုင်းဂွင်းမောင်းနှင်မှု ပုံစံ | ဖက်ရာ အင်တိုင်း |

| ထိန်းချုပ်မှုစနစ် | အရည်ပိုင်း ပြသချက် မျက်နှာပြင် |

| လည်ပတ်မှု အပူချိန်အကွာအဝေး | -20℃~50℃ |

လုပ်ငန်းစဉ် ဇယား:

- ပြင်ဆင်ခြင်း - တိုင်းတာရေးစက်၏ မောင်းနှင်မှု ပူလီနှင့် အလိုအလျောက် ပူလီပေါ်သို့ ပိုက်ဆက်ပြားကို တပ်ဆင်ပါ။

- ချုပ်တားခြင်း - လေအားဖြင့် လှုပ်ရှားသော စနစ်ကို ဖွင့်လှစ်၍ ပိုက်ဆက်ပြားကို အလိုအလျောက် ချုပ်တားပြီး လှုပ်ရှားမှုကို ကာကွယ်ပါ။

- တိုင်းတာခြင်း - ထိန်းချုပ်မှုပြားမှ စတင်ပါ၊ ကိရိယာသည် ပိုက်ဆက်ပြားကို တစ်ပတ်လုံး တစ်ဖြေးဖြေး ဆွဲယူပါသည်။

- ဖတ်ခြင်း။ LCD မျက်နှာပြင်သည် တိုင်းထားသော ကွန်ဗီယာဘီးလုံး၏ ပတ်လည်အနားသို့မဟုတ် အရှည်ကို အလိုအလျောက်ပြသပြီး ခိုင်မာစွာ ပိတ်ဆို့ပေးပါသည်။

- ပြီးဆုံးခြင်း။ ကလပ်စနစ်ကို ဖြုတ်ချပြီး ကွန်ဗီယာဘီးလုံးကို ဖယ်ရှားပါ။

YONGHANG ကွန်ဗီယာဘီးလုံး တိုင်းတာရေးစက်သည် တိကျသော စက်မှုအပ်ပိုင်း၊ ဉာဏ်ရည်မြင့် အီလက်ထရွန်နစ် တိုင်းတာမှုနှင့် တည်ငြိမ်သော လေအားကို ပေါင်းစပ်ထားပြီး ဘီးလုံးအရှည်ကို အတွေ့အကြုံအပေါ် မူတည်နေသော 'ခန့်မှန်းတိုင်းတာမှု' မှ တိကျပြီး ထိရောက်မှုရှိကာ စံသတ်မှတ်ထားသော စက်မှုလုပ်ငန်းစဉ်တစ်ခုအဖြစ် ပြောင်းလဲပေးပါသည်။ ၎င်းသည် တိုင်းတာရေးကိရိယာတစ်ခုသာမက ပစ္စည်းစီမံခန့်ခွဲမှုတိကျမှုကို မြှင့်တင်ရန်၊ ဝယ်ယူမှုနှင့် စတိုက်ကုန်ကျစရိတ်များကို လျှော့ချရန်နှင့် စက်ပစ္စည်းများ ထိရောက်စွာ တပ်ဆင်မှုကို သေချာစေရန် ရှာဖွေနေသော လုပ်ငန်းများအတွက် ထုတ်လုပ်မှုစွမ်းအားကို မြှင့်တင်ပေးသည့် သော့ချက်တစ်ခုလည်း ဖြစ်ပါသည်။ ကွန်ဗီယာဘီးလုံးကို အသုံးပြုမှုနှင့် စီမံခန့်ခွဲမှုတို့တွင် ပါဝင်နေသော ခေတ်မီစက်မှုလုပ်ငန်းတိုင်းအတွက် ၎င်းသည် စံနှုန်းများကို မြှင့်တင်ရာတွင် အကျိုးရှိသော ရင်းနှီးမြှုပ်နှံမှုကို ကိုယ်စားပြုပါသည်။

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MR

MR

MY

MY

KK

KK

UZ

UZ

KY

KY